HDPEスパイラルパイプマシン

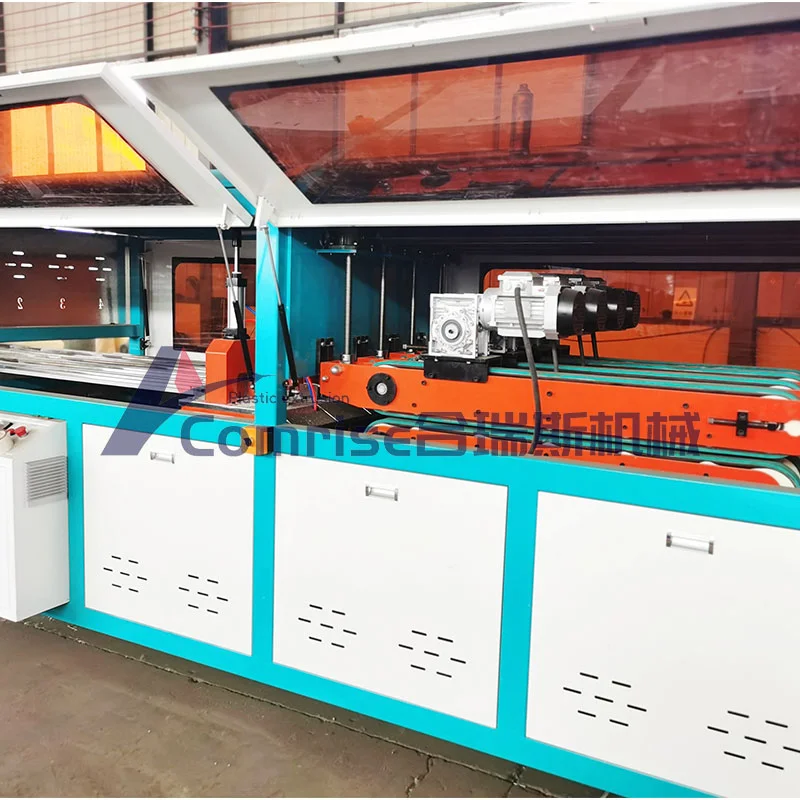

Comrise machinery is a manufacturer specializing in high-quality HDPE spiral pipe machine equipment, with 20+ years of industry experience. Comrise are committed to technological innovation of plastic HDPE hollow spiral pipe machine machines, plastic machinery research and development, design and manufacturing and technical services.

Comrise high quality HDPE spiral pipe machine adopts advanced technology and technology to efficiently produce high-quality HDPE hollow wall wrapped pipe products. This HHDPE hollow spiral pipe machine product has excellent corrosion resistance, high temperature resistance, high strength and light weight, and is widely used in water supply and drainage, power cable sheathing and other fields. Our machines also have the advantages of easy operation and high production efficiency.

Comrise team consists of a group of experienced and skilled engineers who can provide you with a full range of technical support and after-sales service. Comrise will tailor the most suitable solution for you based on your actual needs and ensure the efficient and stable operation of the machine.

If you are interested in our products or have any questions, please feel free to contact us. We look forward to establishing a long-term cooperative relationship with you and providing you with high-quality products and services.

GET A QUOTATION NOW

HDPE hollow spiral pipe machine introduction:

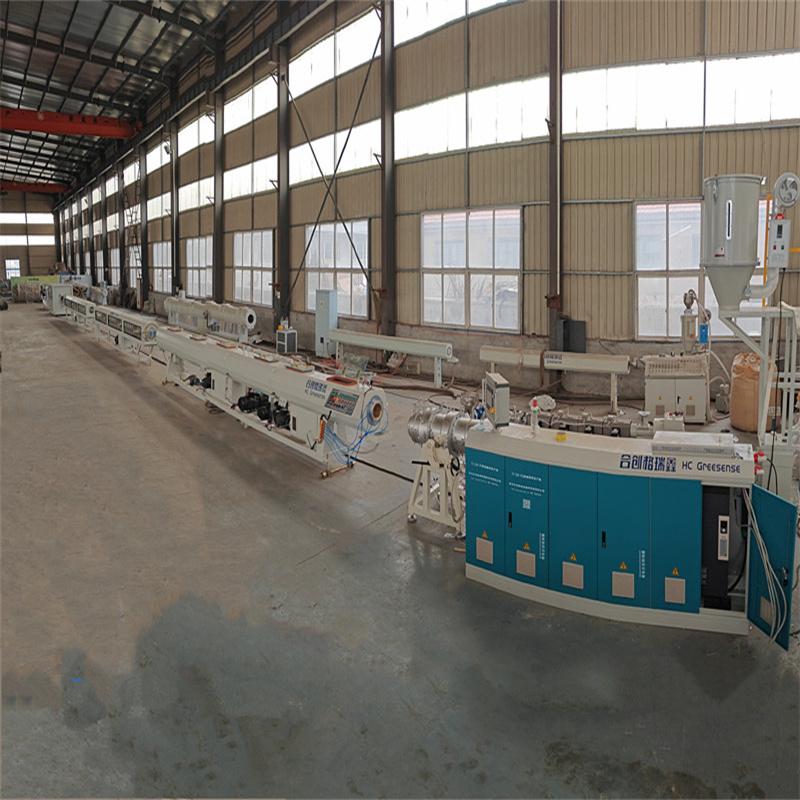

Comrise Whole sale high quality HDPE hollow spiral pipe machine, HDPE Large diameter krah pipe machine, HDPE Large Diameter continuous carat drainage tube machine, Plastic steel winding pipe production line, HDPE solid wall spiral tank machine, HDPE PE inner rib pipe winding sewage pipe machine, and double plastic composite winding pipe production line with high quality and competitive price.

1. It is a key scientific and technological project in the “Tenth Five-Year Plan” of the country. By introducing and digesting foreign advanced technology, our company has successfully developed large-diameter HDPE hollow spiral pipe machine and put it on the market, which can produce large pipes with a diameter of 200-4000mm.

2. This HDPE hollow wall pipe is an ideal drainage and sewage product that replaces steel pipes and cement pipes.

3. HDPE hollow wall winding pipe is non-toxic, odorless, anti-corrosion, anti-labor, and has good weather resistance (-70~C to +80~C). It can be used underground and on the surface, and is widely used in agricultural and industrial water delivery. project.

4. The production line of HDPE hollow spiral pipe machine has sensitive operation, high output, and stable product size. The complete HDPE hollow wall winding pipe production line provides process formulas and "turnkey" projects.

What is the main features of HDPE hollow spiral pipe machine?

1.Safe and reliable ring stiffness Compared with pure plastic pipes, the reinforced steel strip can easily make pipes, especially large-diameter pipes, have sufficiently safe and reliable ring stiffness.

2. The inner wall is smooth, and the flow resistance is 20 to 30% lower than that of cement pipes. The inner wall of polyethylene (PE) pipes is smooth, the friction coefficient is small, and sediments are not easy to accumulate in the pipe. The friction resistance is almost unchanged after long-term use.

3. Flexible or non-leakage (electrofusion welding, butt welding) connection, good sealing performance and environmental protection performance. Both sealing connection methods can be operated manually with simple tools, no machinery required, very simple and fast, reliable and leak-free.

4. Corrosion-resistant, with a service life of more than 50 years. The service life of high-density polyethylene (PE) pipes can be as long as 50 years.

5. Light weight, few joints, no need for large equipment, easy installation and laying. Light weight, no need for large lifting equipment during installation. It has good axial flexibility, has low requirements on the flatness and solidity of the bottom of the trench during laying, and has strong ability to withstand abnormal stress caused by improper installation.

6. Strong ability to withstand abnormal sudden loads. Pipes can resolve the resulting stress through elastic deformation, preventing pipe joints from leaking or being damaged due to excessive stress and deformation.

7. The comprehensive cost is competitive. Combining the advantages of steel and plastic, the pipe has excellent comprehensive performance.

GET A QUOTATION NOW

PE Storage Tank Producing Machinery main Technical Parameter:

|

Model |

Pipe range(mm) |

Extruder |

Installed power(kw)Loading factor 50% |

Max.Capacity kg\h

|

Overall dimension(L*W*H) |

||

|

|

|

Model |

L\D |

Motor power |

|

|

|

|

HC-800 |

200-800 |

SJ75\33 SJ65\33 |

33:1 |

55 30 |

145 |

290 |

23*10*3.2 |

|

HC-1200 |

300-1200 |

SJ90\33 SJ65\33 |

33:1 |

75 37 |

175 |

380 |

24*10*3.5 |

|

HC-1600 |

800-1600 |

SJ100\33 SJ75\30 |

33:1 |

110 45 |

250 |

540 |

26*11*5 |

|

HC-2200 |

1200-2200 |

SJ100\33 SJ75\30 |

33:1 |

132 55 |

280 |

740 |

32*16*6 |

|

HC-2600 |

1400-2600 |

SJ120\33 SJ75\33 |

33:1 |

132 75 |

260 |

500 |

39*17*6.5 |

|

HC-3000 |

1800-3000 |

SJ120\33 SJ75\33 |

33:1 |

160 75 |

330 |

820 |

42*17*7 |

|

HC-4000 |

2000-4000 |

SJ150\33 SJ90\33 |

33:1 |

250kw 90kw |

440 |

1200 |

48*20*7.5 |

What application fields for plastic HDPE hollow spiral pipe machine?

The plastic winding pipes produced by the plastic winding tube machine winding tank machine or carat tube equipment mainly used for Municipal engineering buried drainage, sewage pipes, Construction projects building rainwater pipes, underground drainage pipes, ventilation pipes,Road works sewage pipes in industrial areas, sewage collection pipes in landfills large airports and wharf projects drainage and sewage pipes.

GET A QUOTATION NOW

Why choose us:

1. Adopt high efficency single screw extruder to ensure high efficiency and high quality plastic extrusion.

2. Adopt composite die head molds, spiral rotation forming, exquisite structure, unique design, to ensure high quality hdpe hollow wall pipe extrusion.

3. Plastic pipe production line easy to operate, stable and reliable quality.

4. The plastic hdpe pe winding pipes can be used in plastic inspection wells , septic tanks, and the installation is convenient and safe for construction.

5. It can produce anti-static gas exhaust pipes for mining.

6. Use special pipe fitting connections for convenient connection and economical construction.

Contact details:

Email: sales@qdcomrise.com

Mobile:+86-13780696467

Whatsapp/Wechat:+86 13780696467

- View as

スパイラルチューブ巻き機

Comriseは、地下の下水の建設または建物の使用にスパイラルチューブ巻き機を提供することを専門とする専門企業です。 Comriseは、さまざまな種類のパイプを作成できるさまざまなマシンを提供し、それぞれに独自の利点があります。 Comriseの専門家チームは、顧客と協力してニーズにぴったりのソリューションを見つけることができ、カスタマーサービスに誇りを持っています。 Comriseを使用すると、スパイラルチューブ巻き機で最高の品質の製品とサービスを利用できることを確認できます。

続きを読むお問い合わせを送信ポリマー貯蔵タンク押出生産ライン

Comrise Machineryは、最先端のポリマー貯蔵タンク押出生産ラインを提供することに加えて、優れた顧客サービスも提供しています。 Comriseチームの専門家チームは、顧客が当社の製品やサービスについて持っている可能性のある質問に答えるために常に利用できます。 Comriseは、私たちの速い応答時間と、顧客と協力して問題の解決策を見つける能力に誇りを持っています。

続きを読むお問い合わせを送信スパイラルパイプ形成マシン

Comriseでは、すべての顧客が同じニーズを持っているわけではないことを理解しています。これが、さまざまなサイズとタイプのパイプを作成できるスパイラルパイプ形成マシンを提供する理由です。 Comriseの専門家は、顧客と協力して、特定のニーズと要件に合った完璧なマシンを見つけることができます。

続きを読むお問い合わせを送信HDPE Costal Sea Intake Weholite Pipe Extrusion Line

Comrise Machinery Co。、Ltdは、プロの中国HDPE Costal Sea Intake Weholite Pipe Extrusion Line Manufacutureです。 HDPE Costal Sea Intake Weholite Pipe Extrusion Line機械は、200mmの最大4000mmのパイプ直径を生成できます。 50年間使用することができ、低コストのアセンブリや簡単な動作など、酸、アルカリ、塩などの耐食性などの多くの利点があります。最近のセメントパイプと鋳鉄パイプの置換としてなりつつあります。下水および排水管として広く使用されています。

続きを読むお問い合わせを送信ソリッドウォールスパイラルパイプマシン

China professional manufacture comrise offer solid wall spiral pipe machine for customers who require a smooth surface on the inside of their pipes. These pipes are ideal for applications where the smooth flow of sewage is essential, such as in hospitals or laboratory facilities. So if you're looking for a trusted, reliable partner for your smooth wall spiral pipe manufacturing needs, look no further than Comrise. Contact us today to learn more about our solid wall spiral pipe machine and how it can benefit your business.

続きを読むお問い合わせを送信鋼製強化HDPEスパイラル巻きパイプマシン

China Comrise Steel補強HDPEスパイラル巻きパイプマシンは、Comriseが提供するもう1つのタイプの巻線機械です。高強度の鋼鉄線をねじれ、高強度のポリエチレンで作られたヘリックスに作られたスチールワイヤを補強することで補強されたスチールワイヤーフレームポリエチレン複合パイプを使用します。鋼線フレームは、PEの修飾材料に属する一種の優れた結合材料である高強度粘着樹脂層の外側および内側のポリエチレンと密接に接続されています。加熱条件でPEのように完全に溶けることができますが、その極性結合には鋼と強い接着特性があります。粘着性樹脂のため、パイプの組成により優れています。

続きを読むお問い合わせを送信