75-250mm HDPEパイプマシン

お問い合わせを送信

一般情報

- 製品仕様:

- 生産ライン名:PEパイプ生産ライン

- モデル:φ50-φ160

- パイプ仕様:φ50。 φ63、φ75、φ90、φ110 、φ125、φ140、φ160

| 押出機モデル |

原材料 |

出力 | モーターパワー |

| TS75×38 |

PE80 、PE100、PPK8003 |

450-500kg/h |

132kw |

| TS55×33 |

PE80 、PE100、PPK8003 |

80kg/h |

22kw |

| TS25×25 |

PE80 、PE100 |

5-8kg/h |

1.5kw |

今すぐ引用してください

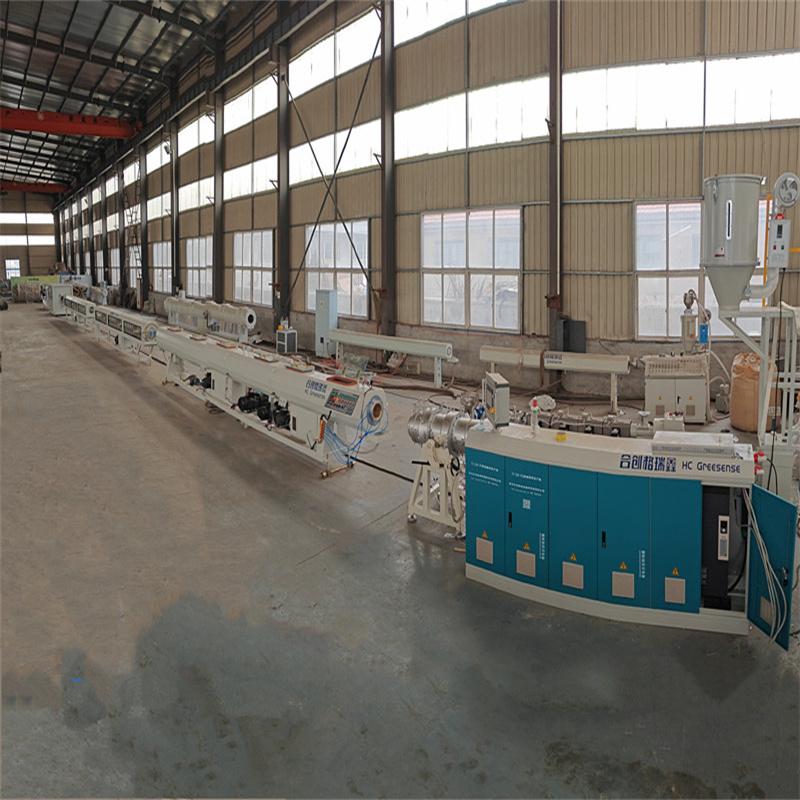

高効率75-250mm HDPEパイプマシン---高効率シングルスクリュー押出機

最適化されたネジと新しいスロットスリーブデザインの使用により、押出機には次の利点があります:高い可塑化速度、均一な溶融物、連続的で安定した生産。高トルク、長寿命、低ノイズを備えた高性能ギアボックスリデューサー。駆動モーターはACモーターです。

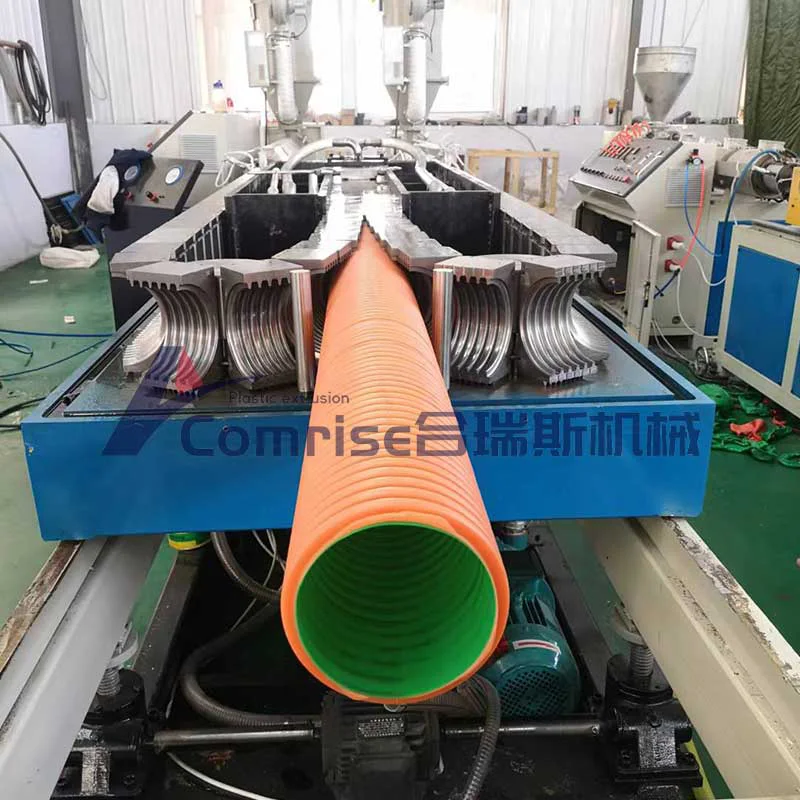

Comrise High Speed 75-250mm HDPEパイプマシン---交換可能なコア金型を備えた複合マシンヘッド

(カビのコアオイル温度制御、真空吸引スーパー冷却は、パイプの内壁に使用され、内側の水リングの高速冷却はサイジングスリーブに使用されます)

Comrise安価な価格75-250mm HDPEパイプマシン---真空サイジングタンク

真空シェーピングテーブルの主な機能は、パイプをサイズと冷却することです。フィルターシステムとバイパス循環経路が水循環経路に設置されており、水位と温度の自動監視もあります。サイジングプレートは、真空シェーピングテーブルに取り付けられています。

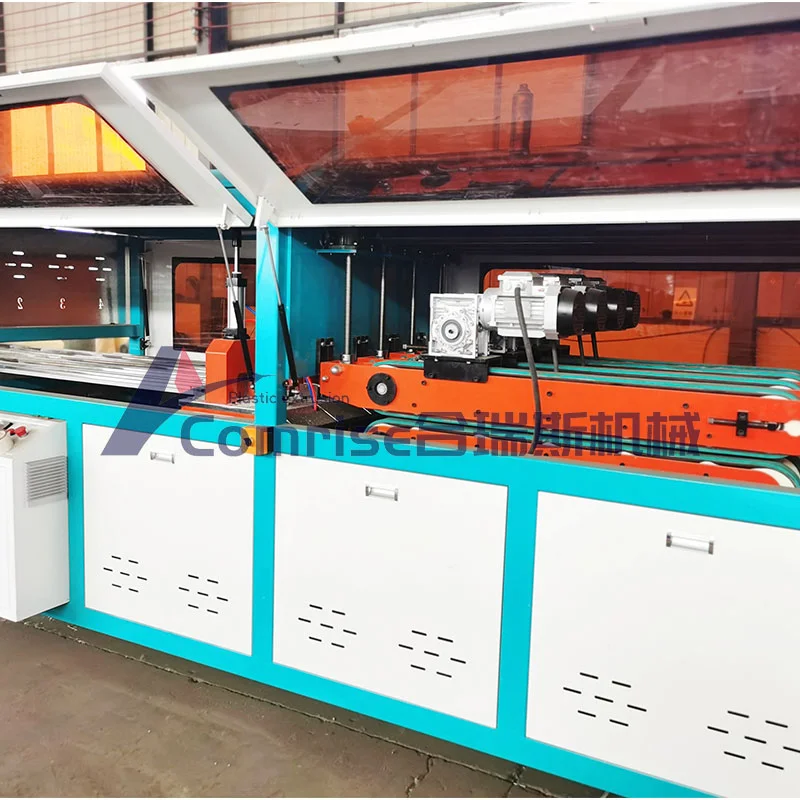

Comrise簡単なメンテナブル75-250mm HDPEパイプマシン--- 4 Claws Crawler Tractor

トラクションデバイスは、コンパクトな構造、メンテナンスフリー構造、および操作中の絶対的な安定性を備えたパイプを継続的かつ安定して引っ張るように設計されています。

Comrise stable 75-250mm HDPEパイプマシン---ダスト切断機なし

長さを正確に測定して切断するために、トラクションマシンに取り付けられた増分エンコーダーと測定ホイールを含む、調整可能な長さの測定デバイスを採用します。

75-250mm HDPEパイプマシン---メーターウェイトコントロールシステム(Walthmac)

メーター重量のオンライン測定および制御システムは、押し出された材料の消費を継続的に測定するために、高精度および高速計量モジュールを採用しています。埋め込まれたコントロールユニットは、生産ライン関連データ、ネジ速度、およびトラクションマシン速度を使用することにより、閉ループ制御システムをリアルタイムで形成します。メーターの重量/押出量を設定した後、メーターの重量制御システムは、設定値に応じてネジ速度とトラクション速度をリアルタイムで調整し、パイプの壁の厚さのリアルタイム制御を達成します。

今すぐ引用してください