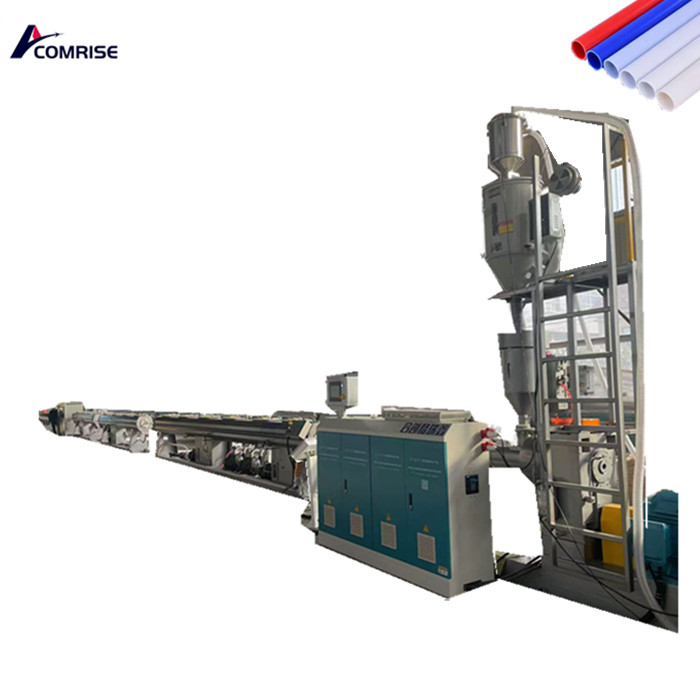

HDPEパイプ高速押出生産ライン

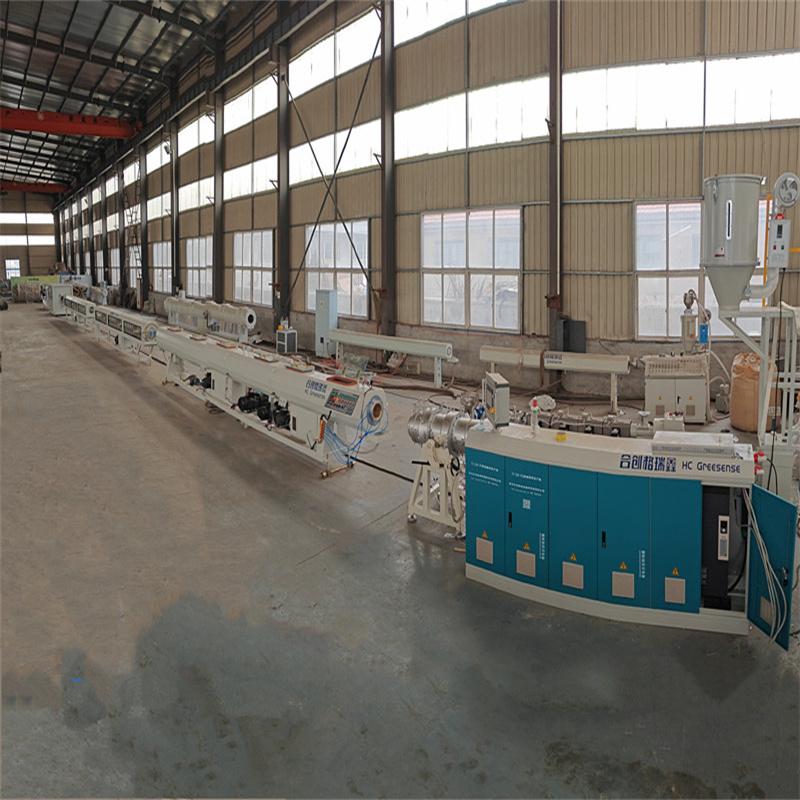

HDPE高速押出生産ラインは、インドやパキスタンなどの国々との効果的な長期協力を確立しました

お問い合わせを送信

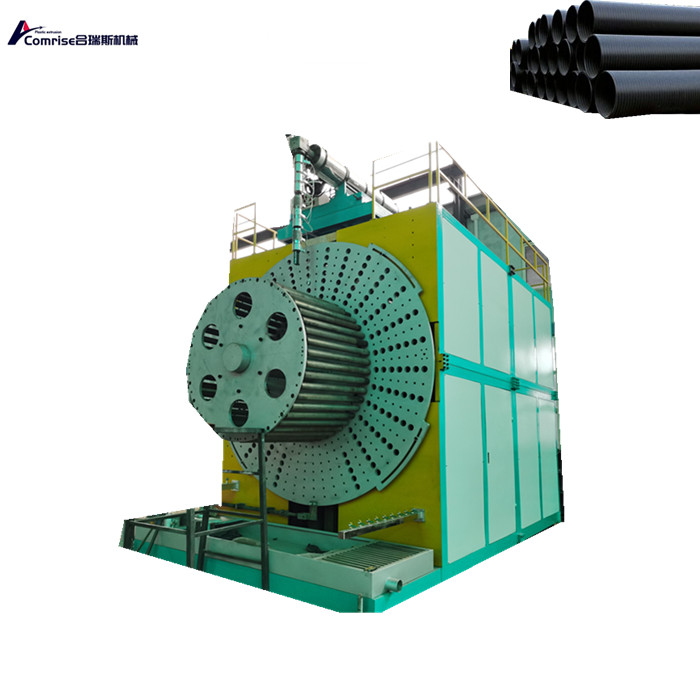

Advantages of 20mm-110mm HDPE Pipe High-Speed Extrusion Production Line:

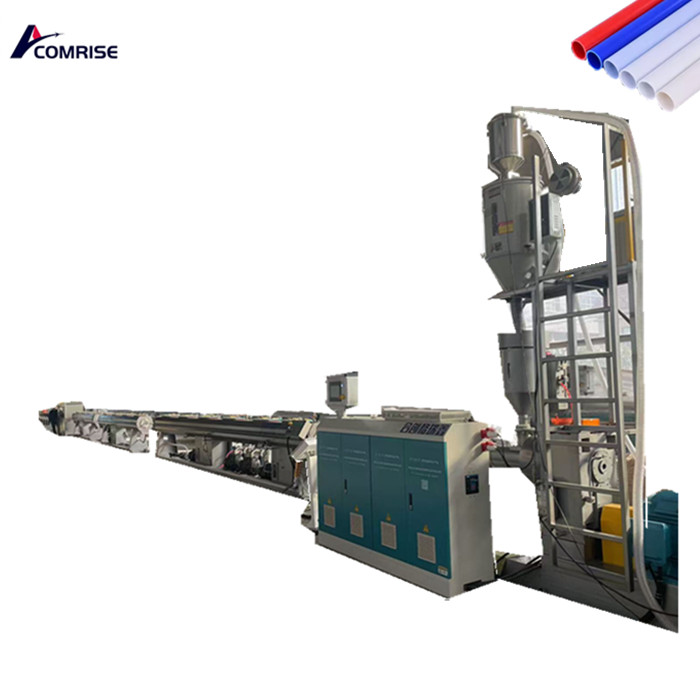

The high-speed production line for PE pipes has a unique structure, high degree of automation, convenient operation, and stable and reliable continuous production. The pipes produced by this plastic pipe production line have moderate rigidity, strength, good flexibility, creep resistance, environmental stress cracking resistance, and good thermal fusion performance, and have become the preferred products for urban gas transmission pipelines and outdoor water supply pipes.

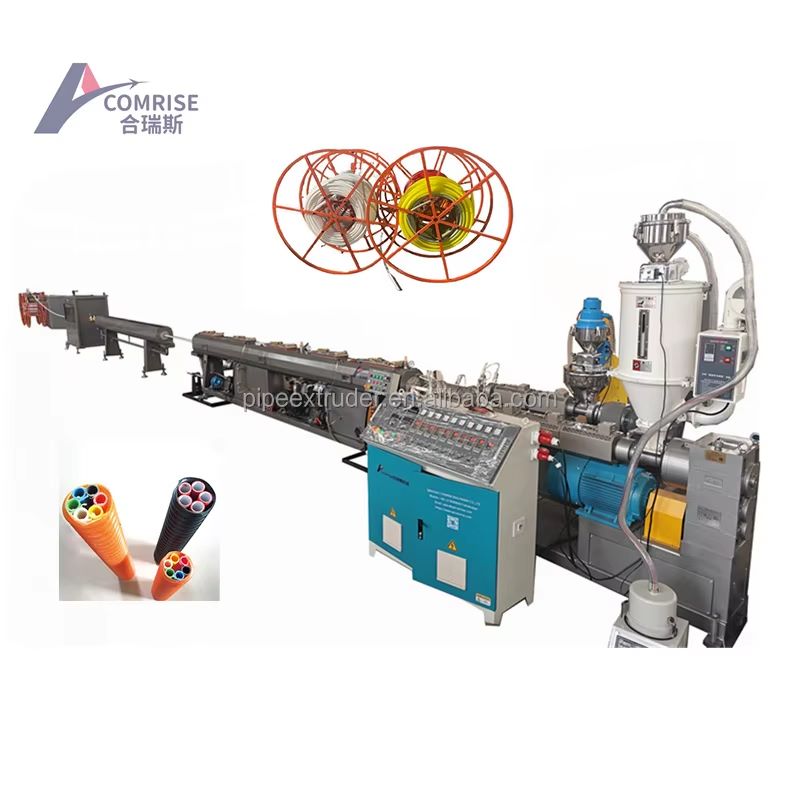

Composition of PE pipe production line: Each pipe production line has two extruders, with the main one using a strong conveying liner and high-efficiency screw, and the other smaller extruder used for extruding the marking line.

Mold and auxiliary equipment: The machine head adopts the latest design of basket type machine head or spiral diversion extrusion tube composite machine head, which has the characteristics of easy adjustment and uniform discharge. The sizing sleeve adopts a unique slotting process and water ring cooling to ensure the forming accuracy of the pipe.

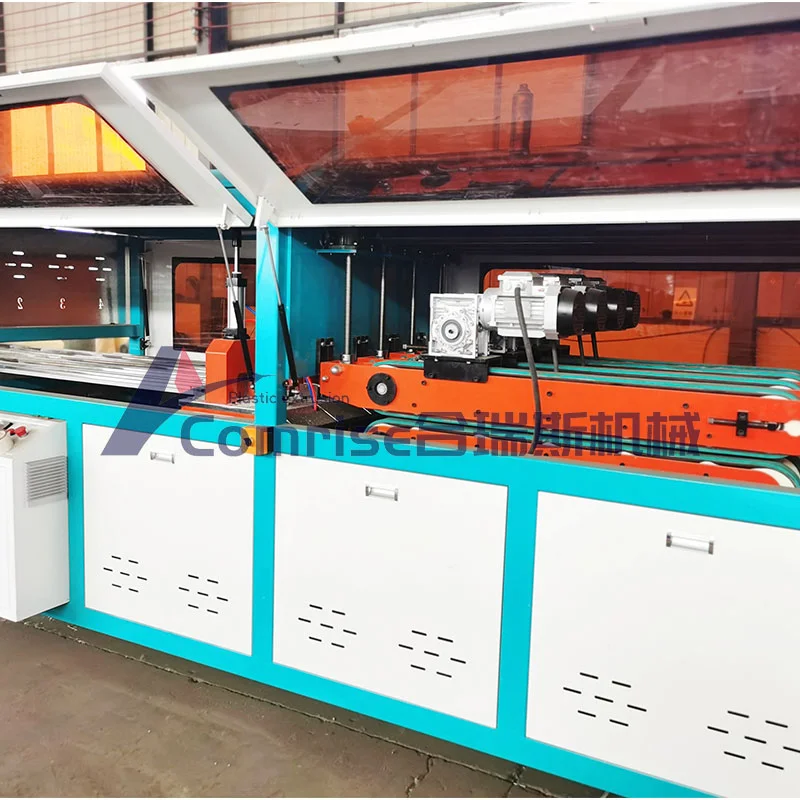

The PE pipe production line adopts PE high-efficiency screws, slotting machine barrels, and strong water jacket cooling, greatly improving the conveying capacity and ensuring efficient extrusion; High torque vertical structure gearbox; DC driven motor. A basket type composite die suitable for polyolefin processing, which not only ensures the stability of efficient extrusion, but also achieves the minimum stress and highest pipe quality caused by low melt temperature. Adopting efficient dual chamber vacuum sizing technology and spray cooling water tank to improve the yield of pipes and meet the needs of high-speed production. Adopting a multi track tractor, the traction force is uniform and stable. Each track is driven by an independent AC servo motor, and the driving technology controlled by a digital controller achieves accurate speed adjustment to achieve height synchronization. Adopting a high-speed and precisely designed cutting machine, the cutting section is flat and equipped with a powerful chip suction device to minimize maintenance work.

Due to its unique advantages, it is widely used in building water supply, building drainage, buried drainage pipes, building heating, gas pipelines, electrical and telecommunications protection sleeves, industrial pipes, agricultural pipes, etc. It is mainly used in urban water supply, urban gas supply, and farmland irrigation.

Our HDPE high-speed extrusion production line has established effective long-term cooperation with countries such as India and Pakistan

GET A QUOTATION NOW