高速単一壁波形パイプ供与ライン

お問い合わせを送信

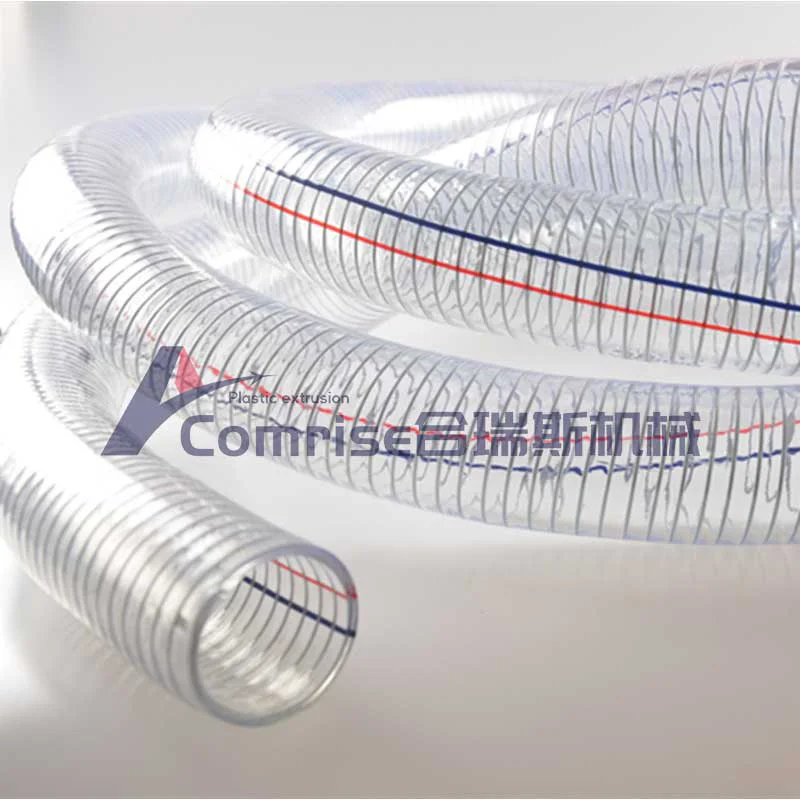

Production Flow: Raw material + master batches→mixing→vacuum feeding →material dryness →single screw extruder→extrusion mould→corrugation forming machine→meter measurer→double winder→finished product inspecting &packing

High Speed Single Wall Corrugated Pipe Prodction Line Features: High and stable extrusion capacity Corrugator mould one mould two size Good water cooling or air cooling system

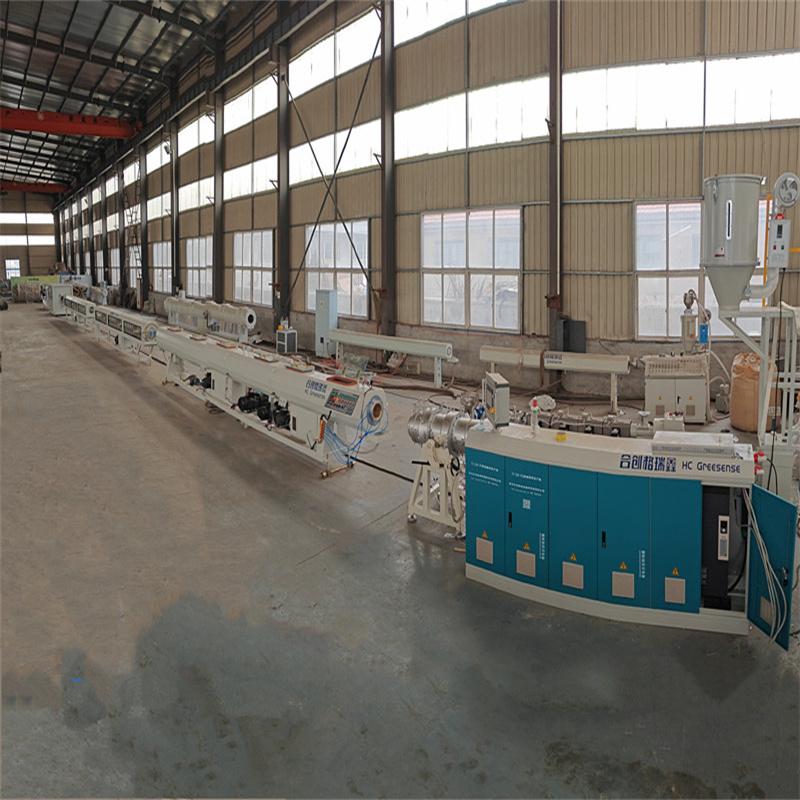

Single Screw Extruder

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality PIPE extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel >940, the surface of screw is chromeplated Feeding bush with water cooling system

Advantages:

All parts are high standard for exporting..use domestic and foreign well known brands Simens motor, ABB frequency converter, Guomao reducer, Omron temprature control,Demaji screw we will according to your pipe diameter and speed match suitable motor to save energy ect.

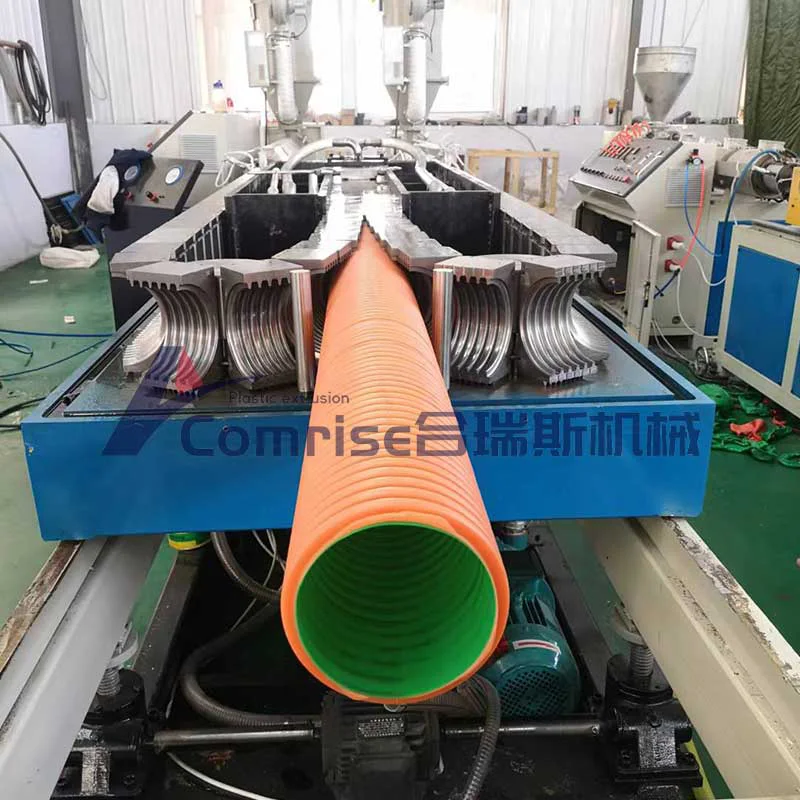

Extrusion Die and The Core Bar and Mouth Mould

1)Material :40Cr , the surface of die is chromeplated, anti-corrosive which better quality than 45#steel2)One set mold have two sizes design can save cost and easy change to another size of mold...this to meet different reqirements from customer.

3)Adopt 55 pairs of big block molds total length 3942 mm

The core bar and mouth mould

Wings Plastic new design,the core bar and mouth mould fit together,when change size,no like the old design change the core bar and mouthe separately,it will be save more than 1h for cleaning the waste material.

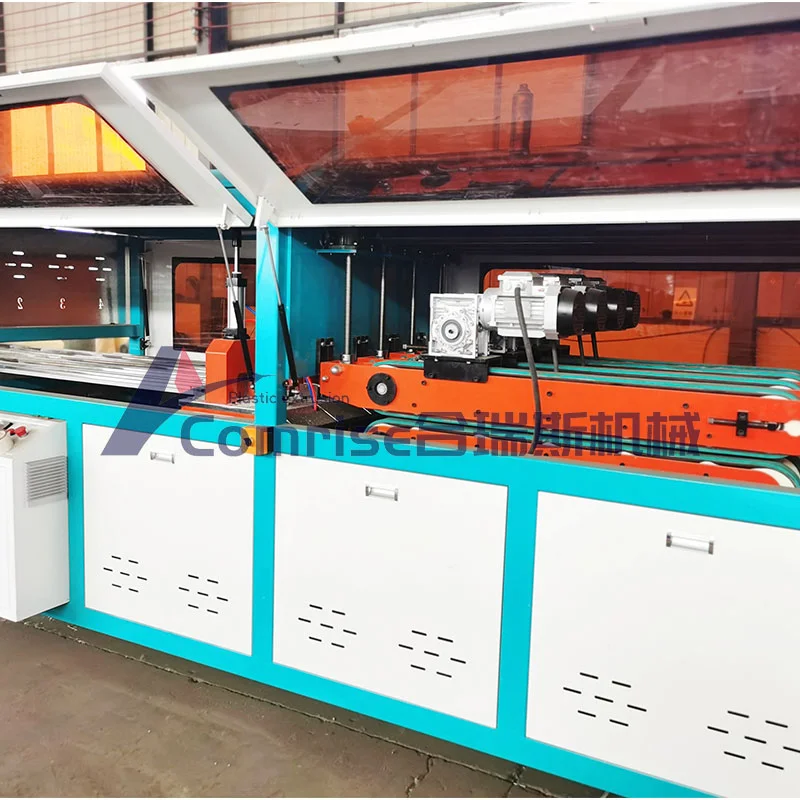

High Speed Forming Machine

Gear driven system with high precision modules and tracks. The track is water cooling system, it could meets 10-30m/min working speed.It is added water cooling and fan cooling two systems.

Forming machine with large cooling area .Temperature fast cooling down.This means the speed will be faster. we test for indian machine speed 20-25mm /minute

Automatic coiler No of wheel: two wheels or one wheel according customer request. Useing delta inverter system, it is automatic adjustment of winding speed.

Double station rewinder Advantages:

1)It has induction device which used for adjust the rewind speed automatically.

2)adopt torque motor and frequency control and pneumatic self open - lock switching.