中空の壁巻きパイプマシンライン

お問い合わせを送信

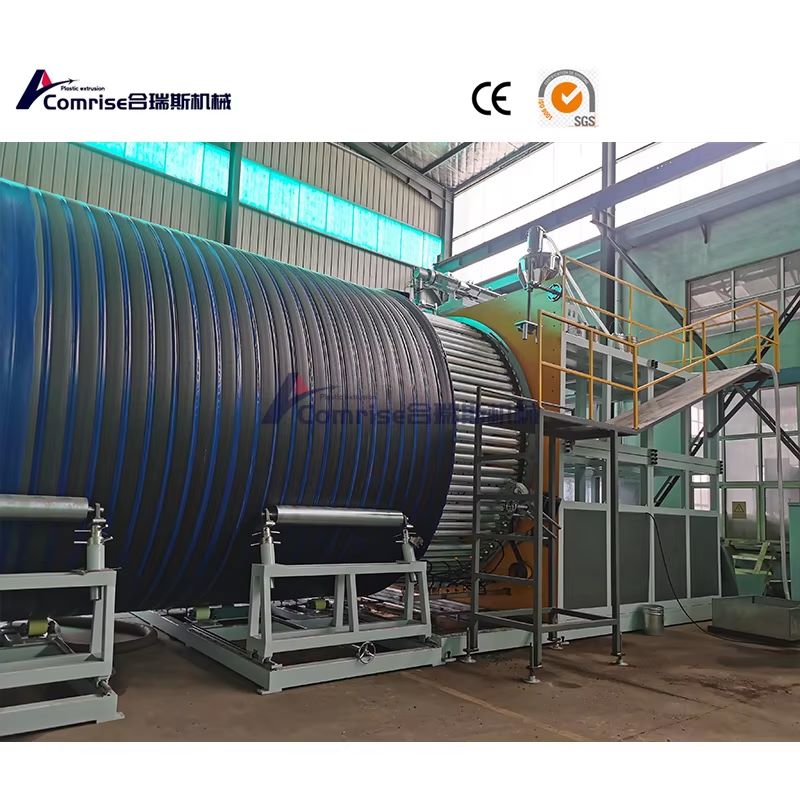

Comrise Hollow Wall Wanding Pipe Machineラインは、主に異なるサイズのスピンドルを交換することにより、200mmから4000mmの範囲の内径のHDPE+PP構造壁スパイラルパイプを生成します。

1。生産プロセス:

中空の壁巻きパイプの材料式は、主にHDPEリサイクル材料、ポリエステル材料、フラックス剤、乾燥剤、およびブラックマスターバッチで構成されています。

フォーミュラの投与量は、HDPEリサイクル材料80-90kg、ポリエステル材料10-20kg、補助フラックス3-4kg、乾燥剤4-5kgおよびブラックマスターバッチ4-5kg、炭酸カルシウム80-90kg、炭酸カルシウム800メッシュ、潤滑剤2-3kgです。

パイプの特性:

中空の壁巻きパイプマシンラインは、高密度ポリエチレンを主要な原料として使用し、巻線成形技術を採用しています。滑らかな内側と外側のパイプの壁、低摩擦抵抗、酸とアルカリの抵抗、腐食抵抗、非毒性、圧縮抵抗、老化に対する耐性の特徴があります。そのサービス寿命は50年以上、建設が簡単で、エンジニアリングコストが低くなっています。中国のセメントパイプ、鋳鉄パイプ、ガラスパイプの代わりになりました。私たちは良いサプライヤーです

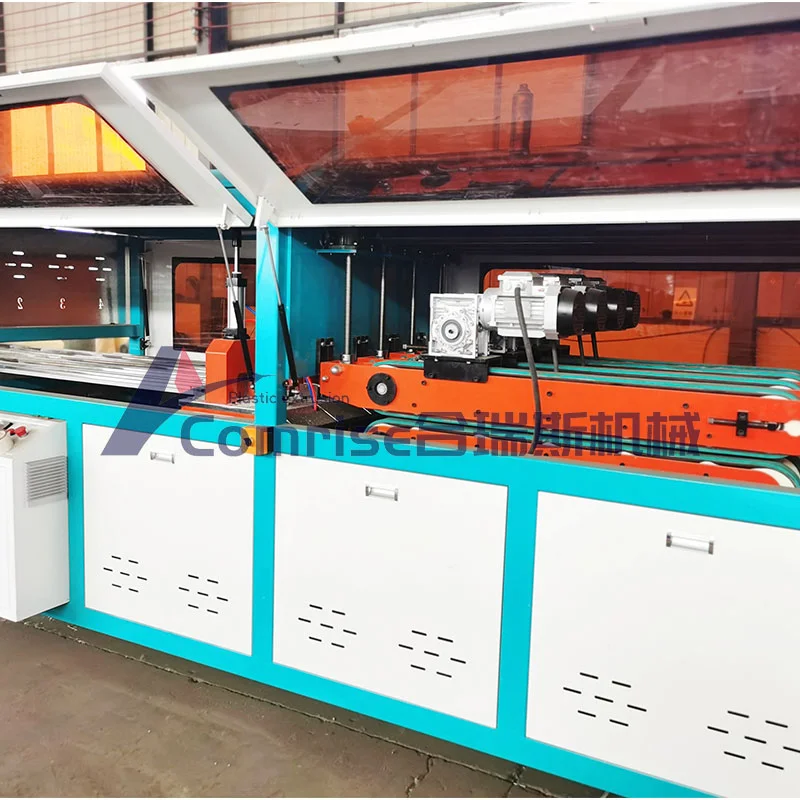

2。中空壁に包まれたパイプの処理技術は次のとおりです。

1)原材料を混ぜて均等に攪拌します

2)パイプの押出機を加熱し、均等に混合した材料をパイプ押出機に加え、溶融材料を加熱し、型から材料を押し出します。

3)パイプ押出機によって押し出されたパイプを形成する真空、続いて水冷。

4)押出機型から押し出された特別な形の構造プロファイルは、所定の位置でローラー型の周りに均一に巻き付けられ、PE溶融材料は同期して押し出され、特別な形の構造プロファイルを全体に溶接し、構造壁パイプの高品質を保証します。

5)巻線形成機の連続噴霧システムは、結合点を冷却し、固めます。

6)所定の長さに応じて切断します。

7)中空壁巻きパイプの加工技術特性は、メルト押出機によって押し出された溶融接着剤の温度が、プロファイルの融解温度よりも10〜20度高いことです。

3。異なるレベルのリング剛性を持つパイプを生産できます。

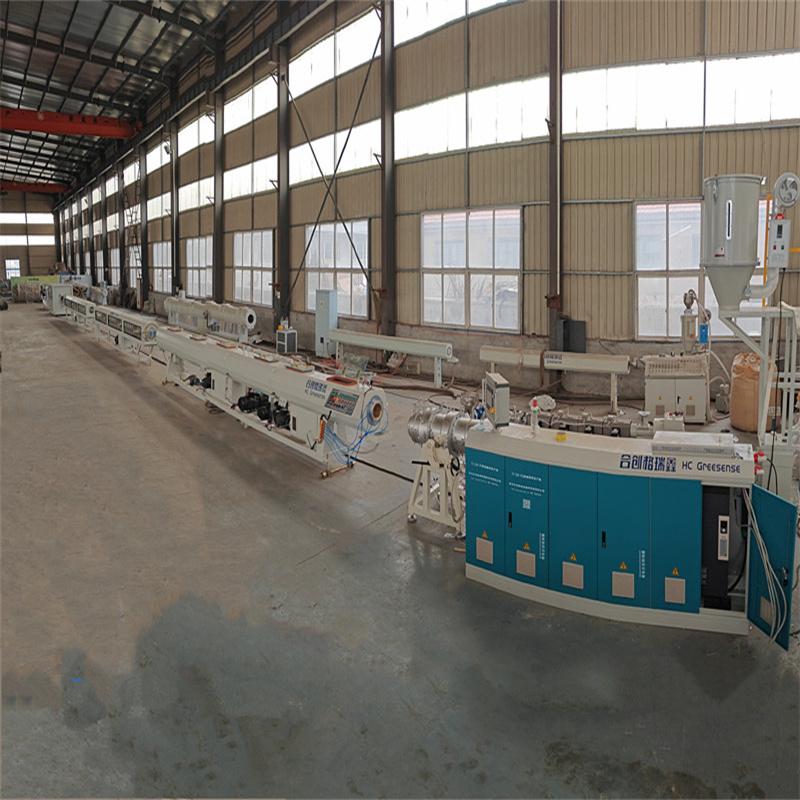

4。効率的な単一のネジ押し出し(ペレットを使用)および省エネの円錐形のツインスクリュー押出機(粉末またはペレットを使用)を提供できます。

5. DN200-DN4000中空壁パイプとDN315-1000ウェルボアパイプを生産できる完全なモデル仕様。

6.パイプラインの特性:内側と外壁は滑らかで、それらの間に中空の層があります。

7。アプリケーション:

高速道路、地方自治体の建設、住宅地、スポーツフィールド、広場、鉱山、農業カルバート、橋などの畑の排水および下水パイプラインで広く使用されています。

アドバンテージ

大口径のスパイラル創傷パイプを生産するための最適なプロセス

中空壁巻きパイプマシンライン直径:DN200mm -DN4000mm。

サイズは、異なる型に従って作成できます。

生産機器とターンキープロジェクトの完全なセットを提供します。

3年間の保証とすべての生涯後の販売サービス

Dhina Top Factory