MPPパイプ押出機

お問い合わせを送信

MPPパイプは、優れた柔軟性、腐食抵抗、軽量、老化抵抗など、優れた性能を持っています。セメントパイプ、鋳鉄製パイプ、鋼管の代替品になりつつあり、都市の給水や都市ガス伝達などの畑で広く使用されています。 PEパイプは広く使用されています

(1)石油およびガスの送信および流通パイプライン

(2)都市および農村の飲料水パイプライン

(3)下水道排水管

(4)化学物質、食品、医薬品、用紙などの産業における液体材料輸送パイプライン

(5)農業灌漑パイプライン

(6)郵便および通信ライン、ケーブル保護パイプなど。

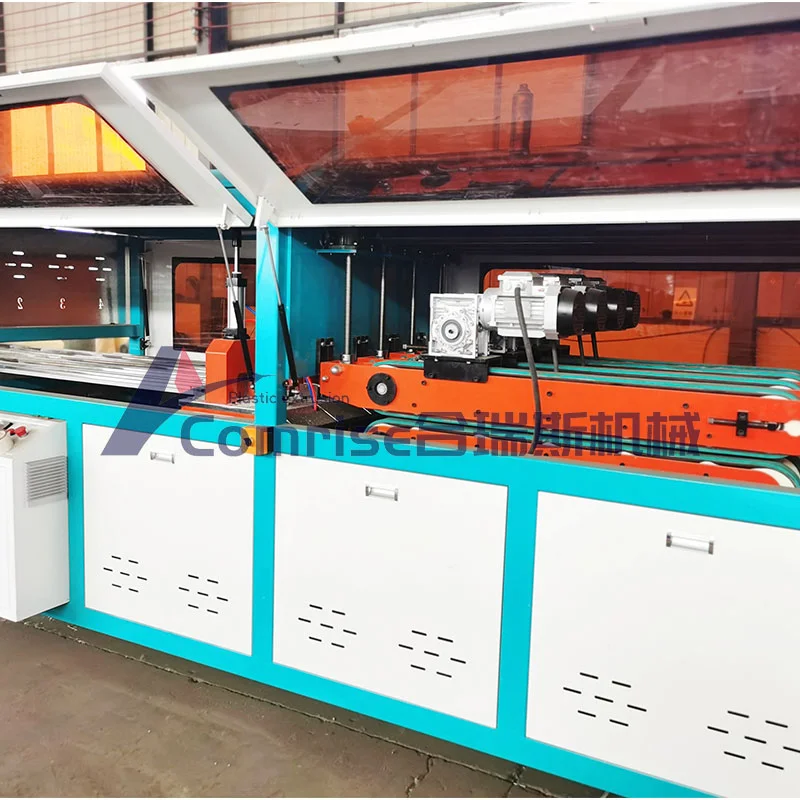

Comrise Factory MPP Pipe Extrusion Machineチューブは、修正されたポリプロピレンを主な原料として使用しています。 MPPは、高速道路、鉄道、建物、川底などの特別なエリアにパイプラインとケーブルを敷設することを含む建設プロジェクトであり、大規模なdr、掘削、道路損傷を必要としません。

従来の「掘削埋設パイプ法」と比較して、非掘削電力は現在のパイプラインエンジニアリングの環境要件を満たし、空気に浮かぶほこりや従来の建設によって引き起こされる交通渋滞などの妨害要因を排除します。

この技術は、サイト保護エリア、市内中心部、作物と農地の保護エリア、高速道路、川など、実行不可能な地域で掘削作業のためのパイプラインを敷設するためにも使用できます。

MPPパイプ押出機

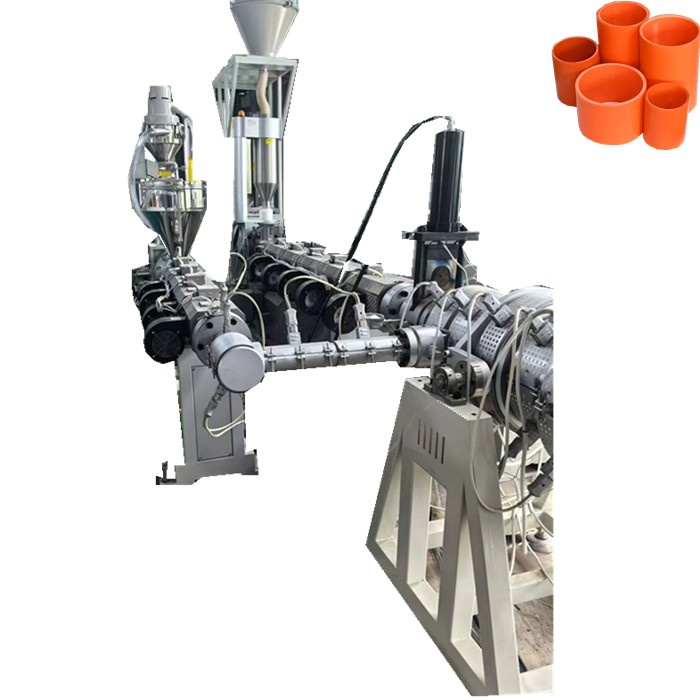

MPPパイプ押出機は、PPおよびMPPパイプ固有の高効率押出機を使用し、ネジ用のバリアと混合ヘッド構造、およびバレル用の新しいタイプのスロッティングマシンバレルを使用します。可塑化と混合効果は良好であり、押し出し能力は大きく、非常に安定しています。特別なネジ構造、優れた可塑化品質、および押し出しチューブの明るい内側と外壁。

私たちが製造する金型ヘッドには、低溶液温度、良好な混合性能、低カビの空気圧、安定した生産の特徴があります。

ヘッド型全体では、50〜250個の範囲のパイプを生成できます。さまざまな仕様の型を交換することにより、さまざまなサイズのパイプを生成できます。型はティンブロンズでできています。

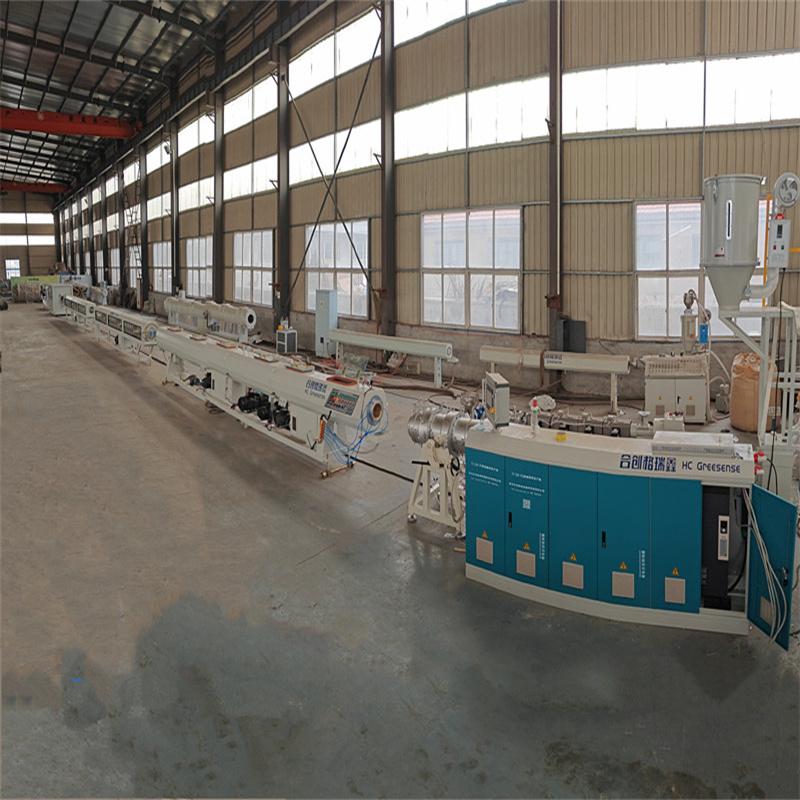

MPPパイプ押出機真空タンクは、主にPVC、PP-R、PE、PP、PE-RTおよびその他のパイプの真空サイジングのためにプラスチック押出機と組み合わせて使用され、パイプの良好な表面滑らかさを確保します。シャーシは、ステンレス鋼SUS304で作られています。体は上下、左右、前後に動き、スプレーは4〜6個のノズルで冷却されます。真空ボックスの自動排水機能。ボックスタイプは、顧客の要件に応じて異なる仕様の固定パイプストレート金型を生成し、16〜630mmの固定パイプストレート金型を生成できます。

今すぐ引用してください