PP中空グリッド波形シートメイキングマシン

お問い合わせを送信

China PP Hollow Grid波形シートメイキングマシンの製造パラメーター:

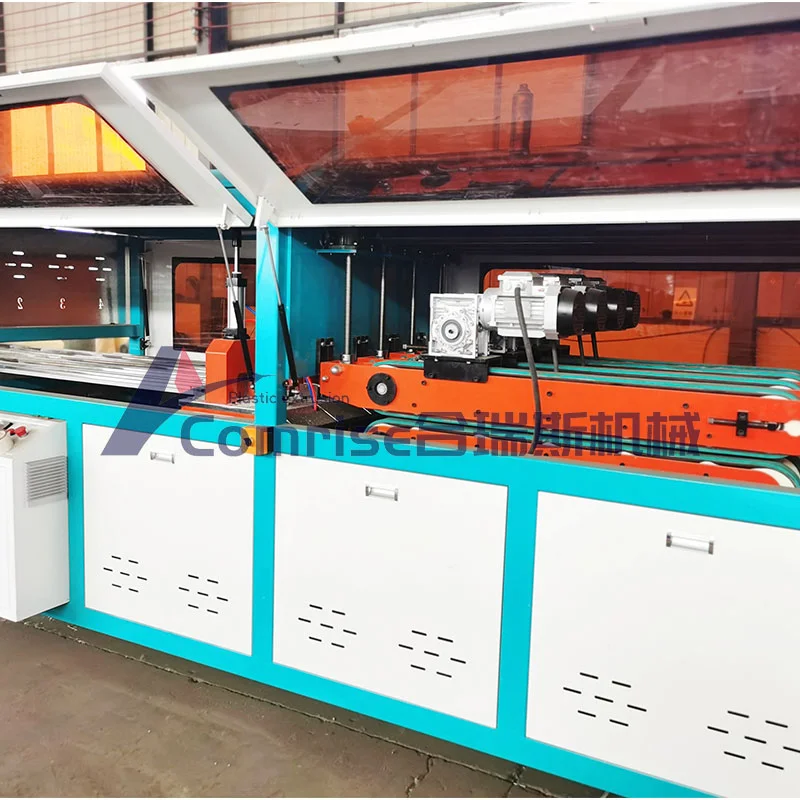

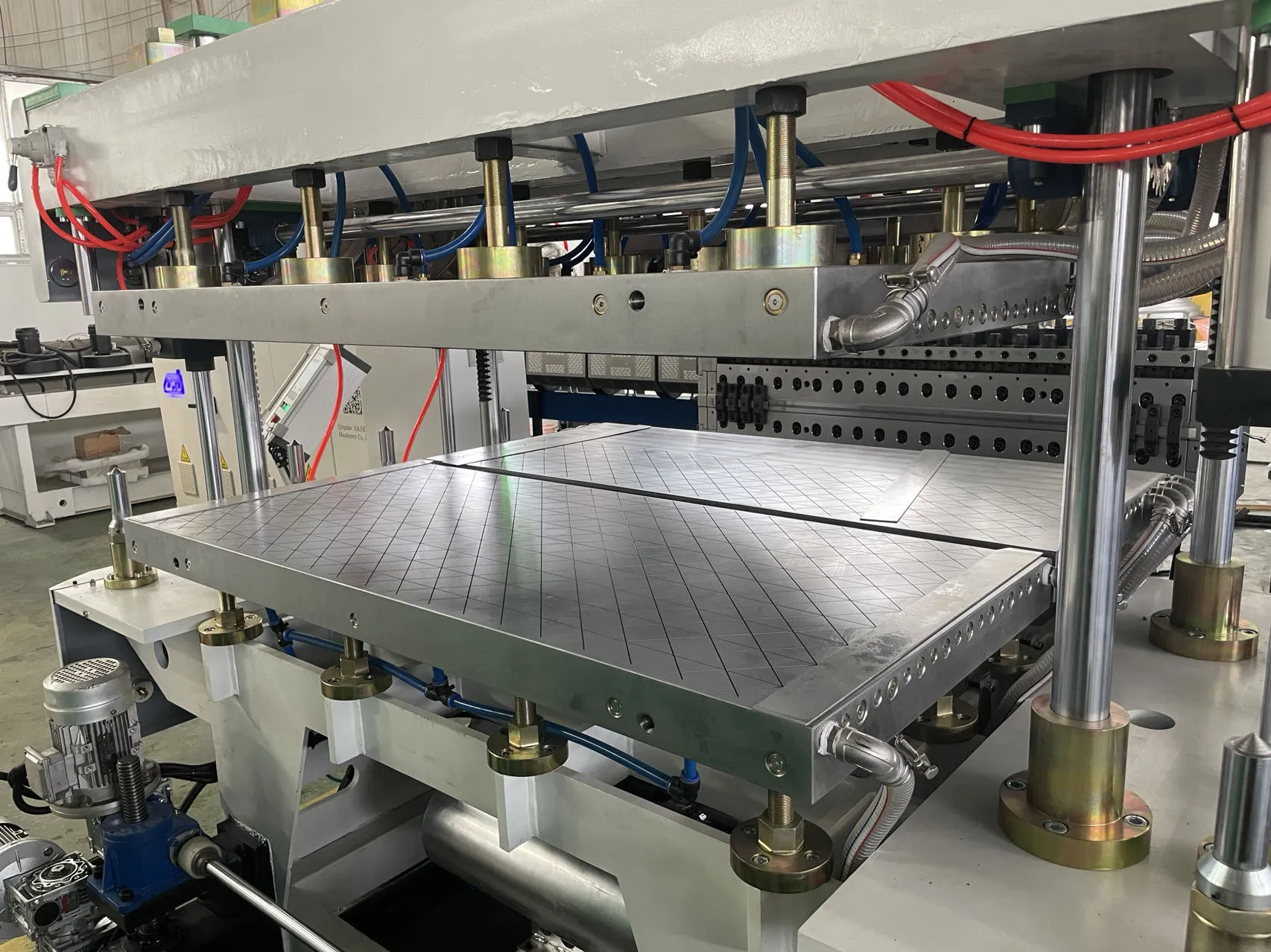

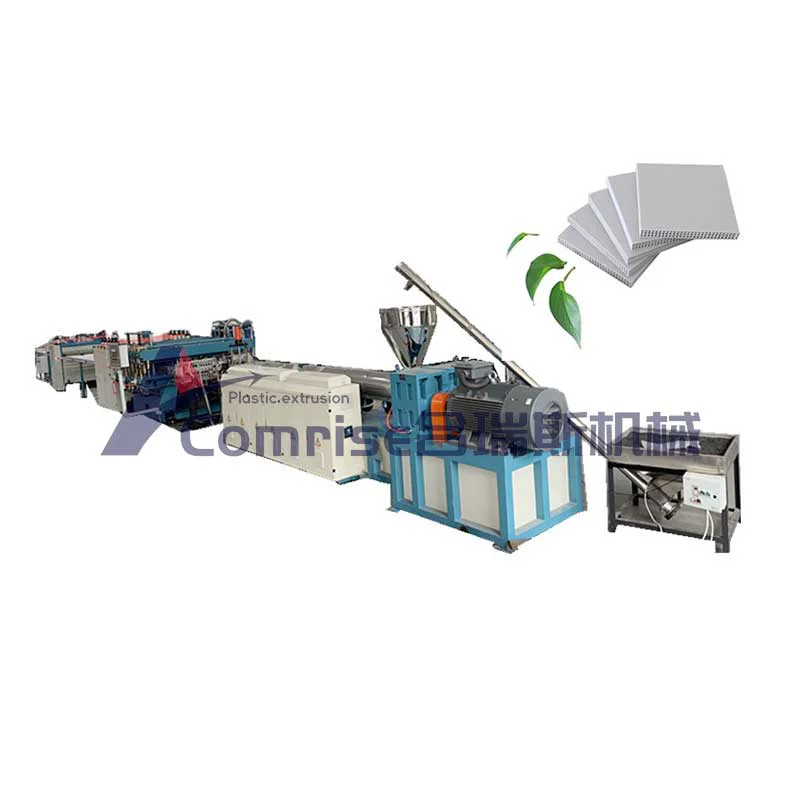

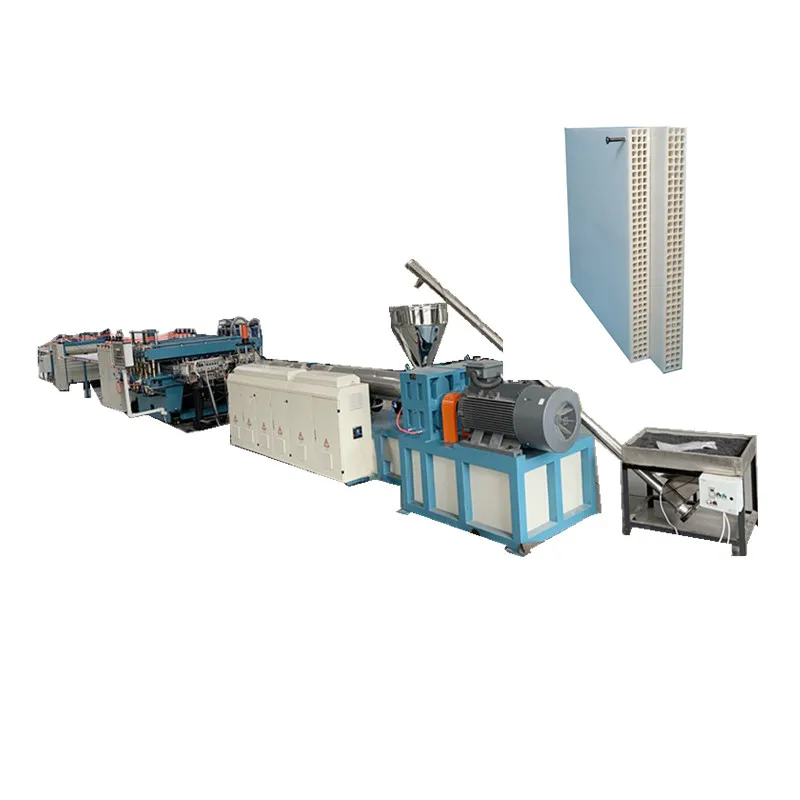

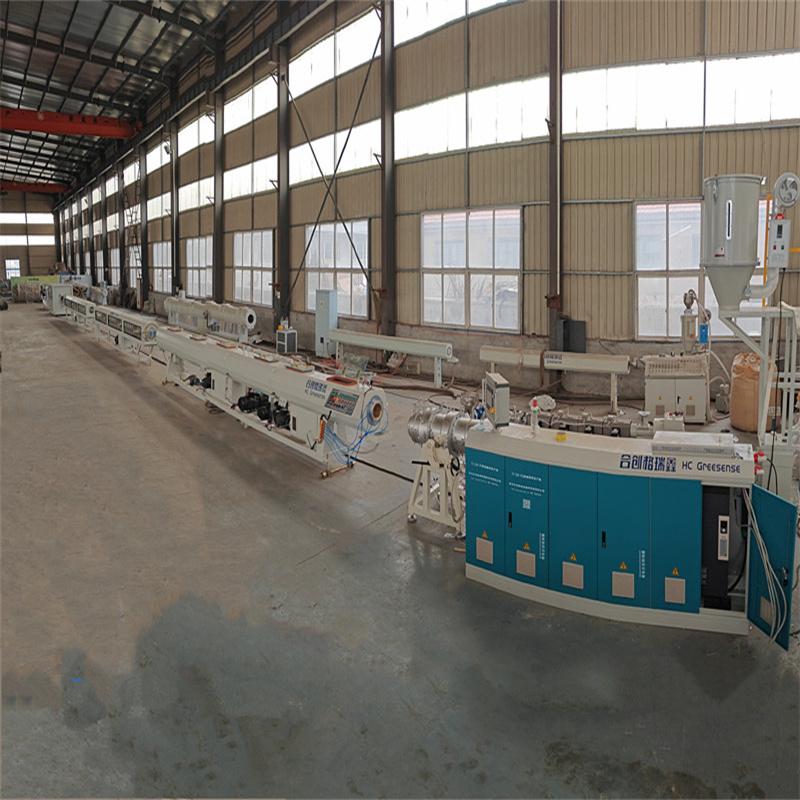

このPP中空のグリッド波形シート製造機のラインは、PP中空/波形シートを生成するために使用されます。派手なPP中空のグリッド波形シートメイキングマシンは、1つまたは2つの単一のネジ押し出し、油圧スクリーンチェンジャー、金型、キャリブレーションプラットフォーム、6つのジェットファン、コロナトリートメント、2つのローラーハルオフマシン、切断機、スタッカーなどで構成されています。

原材料はPP + COCO3です

最終製品:PP/PC中空の波形シート、PP共抽出波形シートのカートン

モデル

シートの厚さ

シート幅

押出器タイプ

主なモーターパワー

HRS-1250

1.5-12mm

1250mm

100/36

55-75kw

HRS-1750

1.5-12mm

1750mm

120/36

75-90kw

HRS-2150

1.5-12mm

2150mm

120/36

90-110KW

HRS-2450

1.5-12mm

2450mm

120/36

90-110KW

HRS-2800

1.5-12mm

2800mm

120/36

132kw

ComriseカスタマイズされたPP中空グリッド波形シートメイキングマシン製品アプリケーション:

Comrise Machineryによって生成されるPP中空のグリッドシートは、軽量、衝撃と油耐性、および防水です。アプリケーションには、パッケージングコンテナ、ディスプレイパネル、毎日の使用アイテム、文房具、建築材料の保護パッケージが含まれます。 PPは、ターンオーバーボックス、コンポーネントボックス、プラスチックパーティションなど、あらゆる形状と製品の種類に形成できます。これは、電子部品の保護に広く使用されている優れた材料です。

高度なPPホローグリッド波形シートメイキングマシンの生産プロセスにおける質問とソリューションは何ですか?

Q:なぜボードの表面は全体として不均一で波状に見えるのですか?

A:成形テンプレートに不十分な真空圧力は、真空吸引力を調整する必要があります。

Q:ボードの表面にしわ欠陥の理由は何ですか?

A:カビのコアエアホールのブロック、カビのコアエアホールのクリーニングが必要です。

Q:なぜボードの表面にクラスター化された波パターンが現れるのですか?

A:金型のこの領域からの材料の急速な放電により、材料が圧縮されたためです。カビの唇を調整し、ボルトを微調整します。

Q:ボードが簡単に平らになり、十分なサポートがない場合はどうすればよいですか?

A:グリッド内の垂直バーの厚さは不十分です。カビの唇の間のギャップを調整して、垂直バーの厚さを増加させます。

今すぐ引用してください