PPRパイプ押出機

お問い合わせを送信

20-110mm HDPE PP PPRパイプ押出機最新のデザインと16mmまでのサイズのPP PEパイプを生産するための有名な電気ブランドを備えた高速および高出力マシンです。 PEパイプ製造機とPE下水パイプマシンライン高効率スクリュー押出機と高トルクレッカーモーター、精密金型、2つのセクション真空水タンク、運搬およびカッターを含む。このHDPEパイプ押出ラインの場合、最大出力は1時間あたり500kgに達することがあります。

20-110mm HDPE PP PPRパイプ押出機製品パラメーター(仕様)

|

モデル |

パイプの日 |

押出機モデル |

モーターパワー |

max.output/h |

|

HSPE-63 |

20-63 |

HSH60/38 |

90 |

450 |

|

HSPE-110 |

20-110 |

HSH60/38 |

110 |

500 |

|

HSPE-160 |

40-160 |

HSH60/38 |

110 |

500 |

|

HSPE-250 |

50-250 |

HSH75/38 |

160 |

680 |

|

HSPE-400 |

160-400 |

HSH90/38 |

250 |

1000 |

|

HSPE-630 |

280-630 |

HSH90/38 |

280 |

1100 |

|

HSPE-800 |

315-800 |

HSH120/38 |

315 |

1300 |

|

HSPE-1200 |

500-1200 |

HSH120/38 |

355 |

1400 |

|

HSPE-1600 |

1000-1600 |

HSH90/38&HSH90/38 |

250+250 |

2000 |

|

HSPE-2000 |

1000-2000 |

HSH90/38&HSH90/38 |

280+280 |

2200 |

今すぐ引用してください

20-110mm HDPE PP PPRパイプ押出機製品の詳細

SJ60/38高効率シングルスクリュー押出器

合金ネジを使用して、ネジとバレルの内面は、ニトリッド、合金スプレー、Xinhengli省エネ貯蓄モーター、GuomaMo High-Torque Reducer、垂直の硬毛の表面還元ボックスで処理され、ガーボックスはらせん縮小と粉砕表面ギアによって強化されます。レベルブレーキ、制御システムはシュナイダーインバーター(または同等のブランド)、シーメンスの低電圧電気コンポーネントを採用しています

Siemensコンタクタ、顧客はメーター重量制御、Siemens PLC制御システム、またはOmronデジタル制御システムを選択できます

オムロンデジタルコントロール

Siemens PLCコントロール

PEパイプ生産ライン機器全体の実行時間はPLCによってプログラムされており、優れたヒューマンマシンが装備されています

シュナイダーインバーター

シーメンスコンタクタ

PLCによる重量計コントロール

省エネセラミック暖房リングと冷却ファン

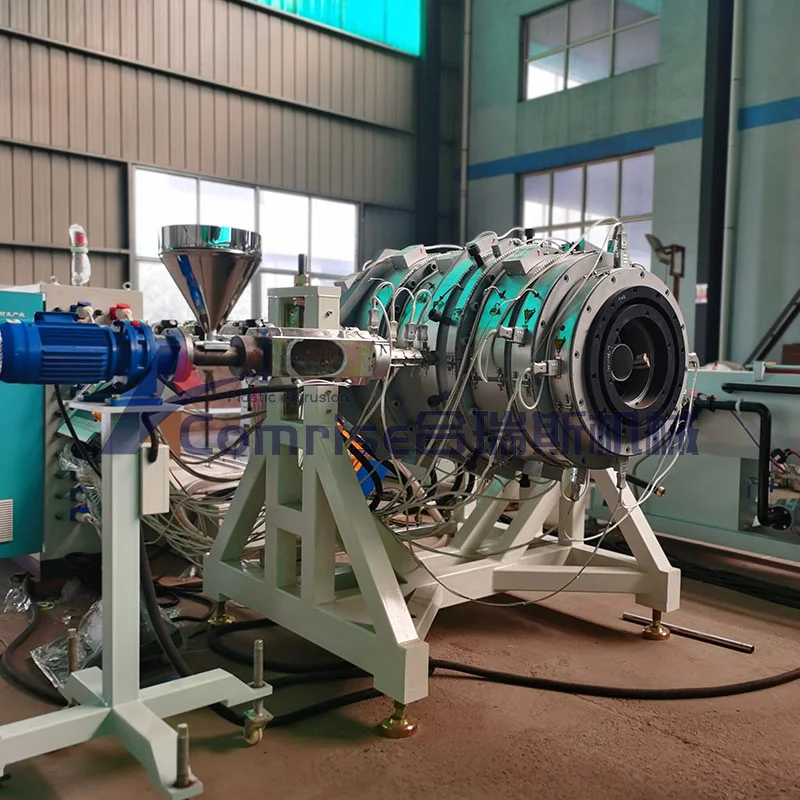

パイプ押出ダイヘッドカビ7

コアとバーのサイズを備えたスパイラル交換可能なダイヘッド金型:φ20-25-32-40-50-63-75-90-110mm

HDPEパイプ向けに設計されたBlue Die Headには、溶融温度が低く、混合性が良好、カビの空気圧が低く、安定した生産の特性があります。

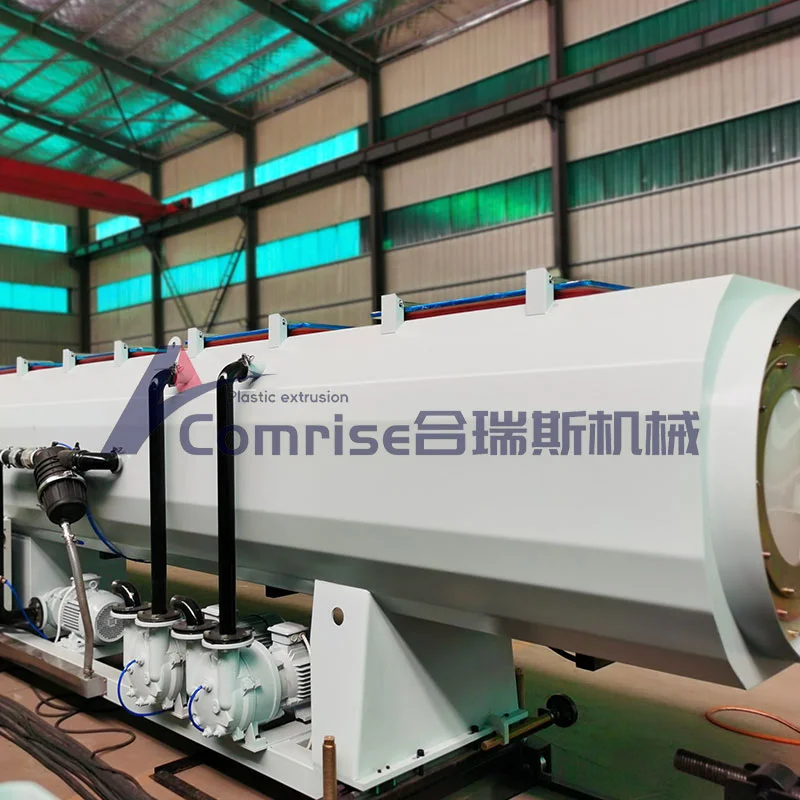

真空水タンク

2セットの真空ポンプ、2セットのウォーターポンプを備えた2つのセクションの真空。HDPEパイプの寸法安定性と丸みを確保する、タンク材料:4mm厚さステンレス鋼

スプレー水タンク

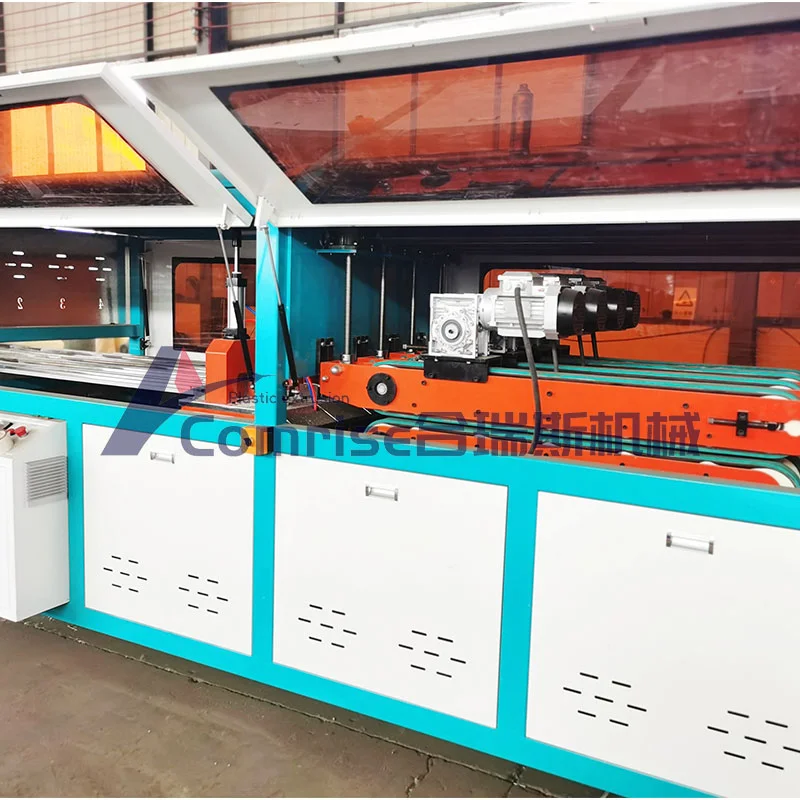

2つの爪PEパイプトラクターマシン

PEパイプトラクターは、輸入速度レギュレータによって駆動および制御されています。これは、安定性が良好で、精度が高く、信頼性が高くなります。

チップレスカッティングマシン

自動フリップラック

より多くの排除写真20-110mm HDPE PP PPRパイプ押出機補助部品の真空ポンプ、ウォーターポンプ、トラクターVタイプブロック、パイプの丸い形状、カッター排除。

今すぐ引用してください

20-110mm HDPE PP PPRパイプ押出機製品機能とアプリケーション

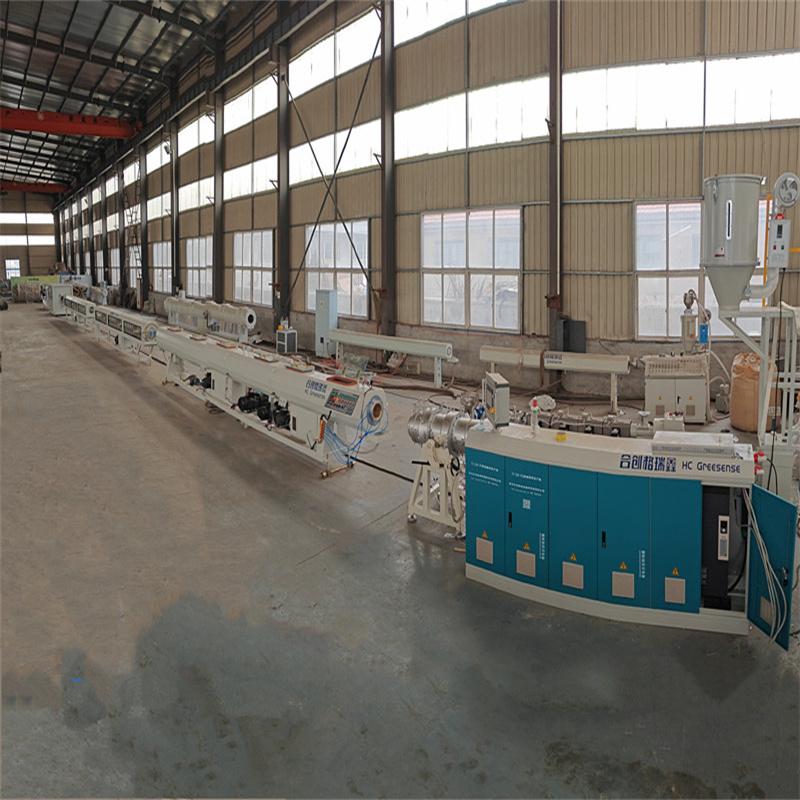

Comriseは新しいテクノロジーの高速を製造します20-110mm HDPE PP PPRパイプ押出機、MPP電気パイプ生産ライン、PE農業パイプマシン、PEパイプを作成するマシンは、信頼性の高いパフォーマンスと高い生産効率を備えています。完成したパイプは、主に農業、給水と排水、建物の給水と排水、ケーブル敷設などで使用されます。

The 20-110mm HDPE PP PPRパイプ押出機生産ラインは、高効率の単一ネジ押出機、真空サイジング水タンク、トラクター、切断機、パイプブラケットで構成されています。

高い効率20-110mm HDPE PP PPRパイプ押出機単一のネジの押出機とトラクターの場合、インポートされた周波数変換速度制御デバイスを採用し、真空ポンプとトラクションモーターはすべて高品質のブランドで作られています。トラクションマシンには、2つの爪、3つの爪、4つの爪、6つの爪、8つの爪、10の爪、12の爪があります。切断機は、ほこりの切断を選択できず、刃の切断や惑星の切断などを見ません。惑星の切断機は、完全に自動的なコンピューター数値制御を採用しています。

PP、PE、ABS、PPR、PEXなどのさまざまな材料のために、いくつかの部品を交換して内壁スパイラルパイプ、内壁中空パイプ、コア層フォームパイプを生産することにより、さまざまな要件を満たすための貴重な技術サポートを顧客に提供できます。

私たちの工場とワークショップについて

Comriseはプロのサプライヤーです20-110mm HDPE PP PPRパイプ押出機研究、開発、製造、販売を統合するサプライヤー。 PEパイプマシンには、高度な技術レベルと主要な技術があります。 HDPE PEパイプメイキングマシンのプラスチック押出ラインは、ヨーロッパ、中東、東南アジア、アフリカ、およびその他の国々への並外れたパフォーマンス、優れた品質、完璧なサービスで、全国でよく販売され、顧客からの良いフィードバックを持っています。

私たちの特許証明書について

配達写真

顧客写真

顧客フィードバック

質問のリクエスト(rfq)

Q1:あなたは製造会社ですか、それとも取引していますか?

A1:機械の製造です

Q1:質問:マシンのどのような利点がありますか?

A1:品質100%保証、有名な電気ブランド、24時間のTechincalサポート、柔軟な支払い期間、ローカルコンサルティングオフィス。

Q2:会社のPaymet期間は何ですか?

A2:30%のデポジットT/T、出荷前の70%の残高、信用状、West Union、Instgram、第三者。

Q3:支払い後、配達にどれくらい時間がかかりますか?

A3:通常の35〜50日の製造時間は、特定のマシンに依存します。

Q4:マシンの保証条件?

A4:12か月、保証期間中に顧客の倉庫の機械領収書からスペアパーツの無料充電から開始します。

Q5:販売後のサービスは何を提供しますか?

A5:販売前のコミュニケーション→設計提案、署名確認→カスタマイズされた生産→出荷前のテストマシン→パッケージと配達→エンジニアのインストール→トレーニングオペレーター→テクニカルサポート