高度なHDPEパイプ押出機

お問い合わせを送信

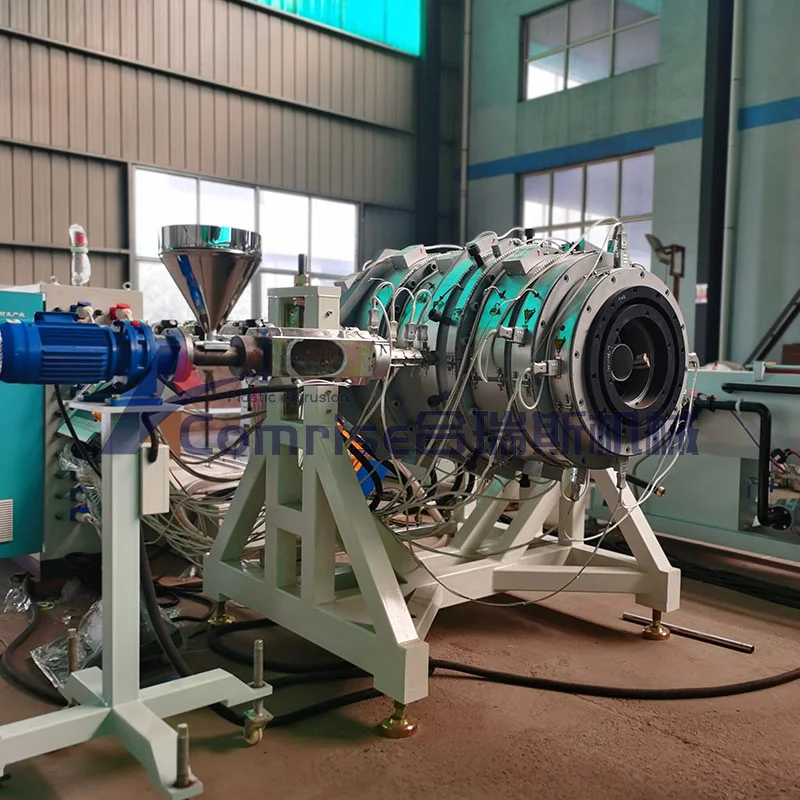

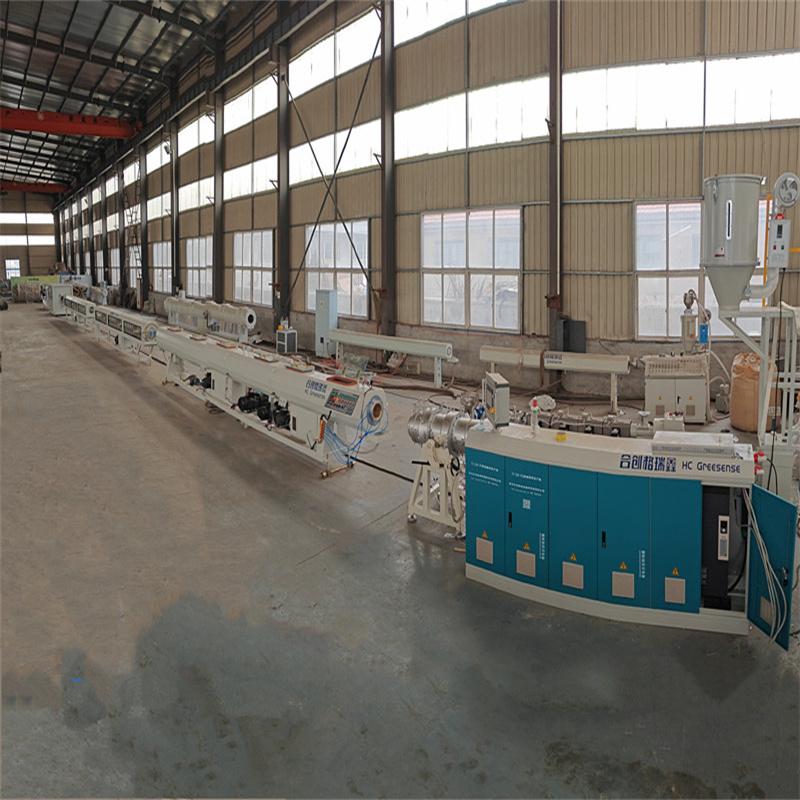

The HDPE pipe production line can be used for HDPE water supply, gas and PPR PE pipes, with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress cracking resistance, creep resistance, thermal connectivity, etc. Therefore, PPR PE pipe extruder is the preferred gas and water pipe for pipeline systems between urban and suburban areas, while HDPE PPR pipe making machine has begun to be used in urban water and gas supply systems. The PE PPR pipe production line is mainly used for manufacturing PE plastic pipes, and the GF series pipe auxiliary equipment production line can also be used for processing other plastics. The extruder and GF series pipe auxiliary equipment production line combine advantages, reliability, applicability, and other characteristics to provide customers with strong certification of high-quality plastic pipes. This production adopts high-efficiency single screw extruder, equipped with extrusion die, vacuum shaping tank, spray cooling tank, drag, planetary cutting machine, and controlled by programmable controller microcomputer system.

Pe pipe production line

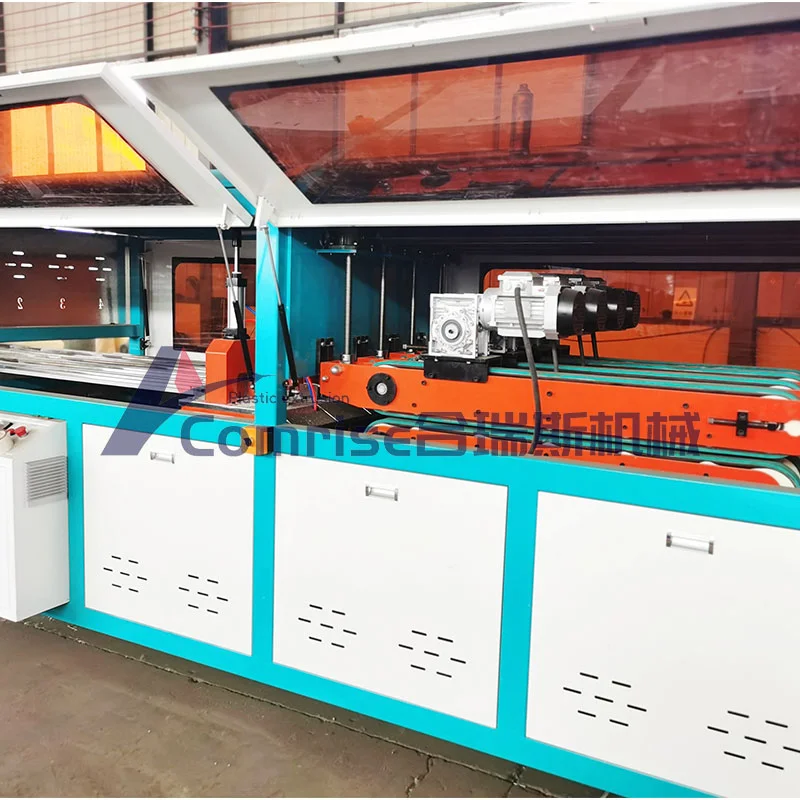

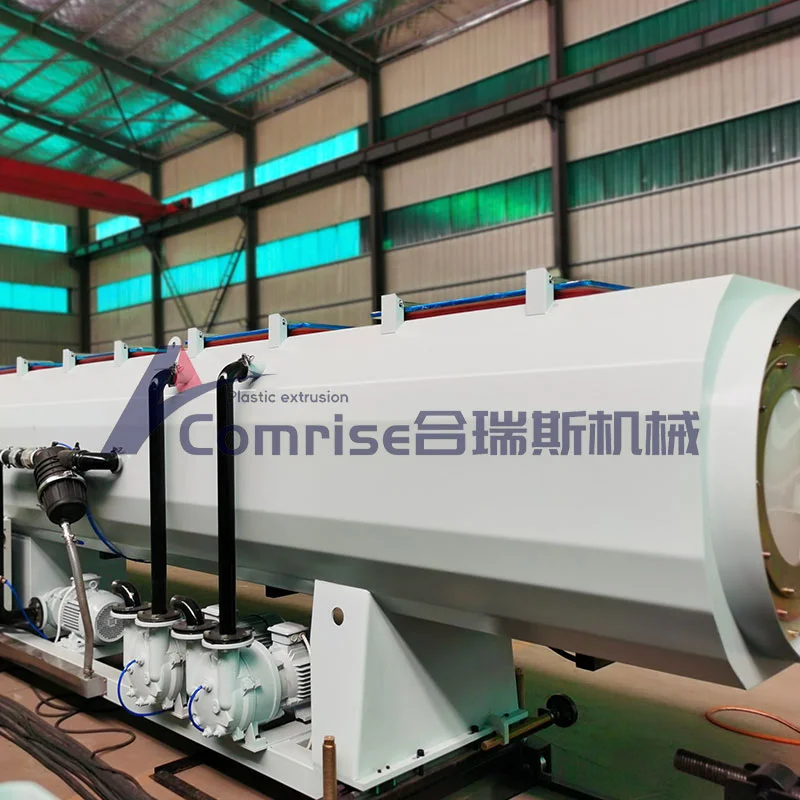

The Advanced HDPE Pipe Extrusion Machine is mainly used for producing water supply and drainage pipes in fields such as agriculture and construction cables. This machine consists of a vacuum calibration tank, traction unit, cutting unit, stacker crane, etc. The single screw extruder and towing unit adopt the famous A/C variable frequency speed regulation device, and the vacuum pump and driving motor are both from well-known brands. The towing unit includes double claw, three claw, four claw, six claw, eight claw, ten claw, twelve claw, etc. It can be applied with dust-proof cutting machine, saw blade cutting machine or planetary cutting machine, and the unit performance is reliable. The production efficiency is high, and special devices can be used to produce inner wall spiral pipe, inner wall hollow pipe and core layer foam pipe. It can also produce PP, PE,ABS,PPR,PEX, Silicon core tube, etc. The planetary cutting machine adopts computer automatic control, which has the advantages of simple operation and reliable performance. It has reached the international advanced level.

1. Capacity: Single screw extruder, suitable for processing high-capacity PE resin

2. Diameter: from 16 to 1200 mm

3. The extruder adopts a large L/D and various mixed structures, which are more suitable for low-temperature extrusion production of PE, PP, PPR.

4. Specially designed spiral mold for PE PP PPR pipes with marked lines, equipped with an internal oil temperature control system

5. The beautiful and practical stainless steel body is a vacuum calibration and spray cooling system. The unique multi section vacuum system ensures the stable sizing and cooling of pipes with marked lines; The special spray cooling system improves the cooling efficiency; The special water position and temperature system make the machine more intelligent.

6. The traction device adopts a special armrest structure, which is easy and convenient to operate; The armrest clamping adopts a mechanical and pneumatic combination system, which is more reliable.

7. The cutting system adopts saw blades and planetary cutting methods; The water collection tank adopts a hydraulic system to ensure a smooth cross-section; Equipped with a dust collection device to ensure a clean working environment.

GET A QUOTATION NOW