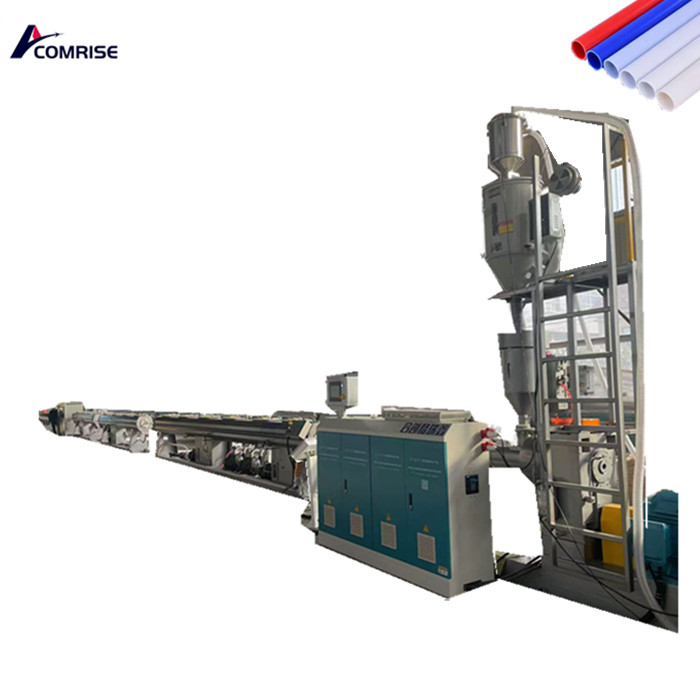

HDPEパイプマシン

お問い合わせを送信

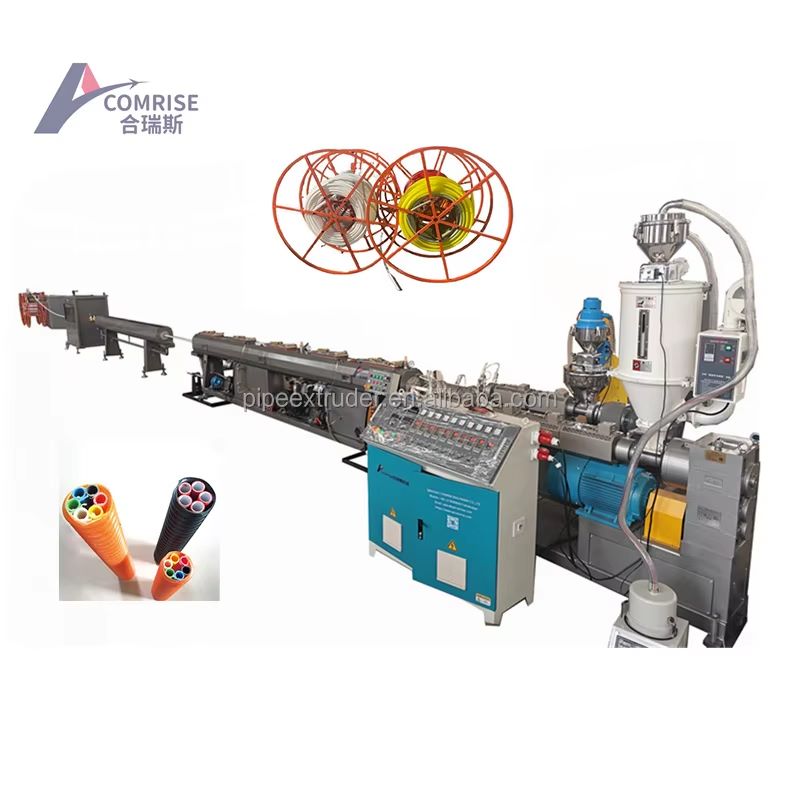

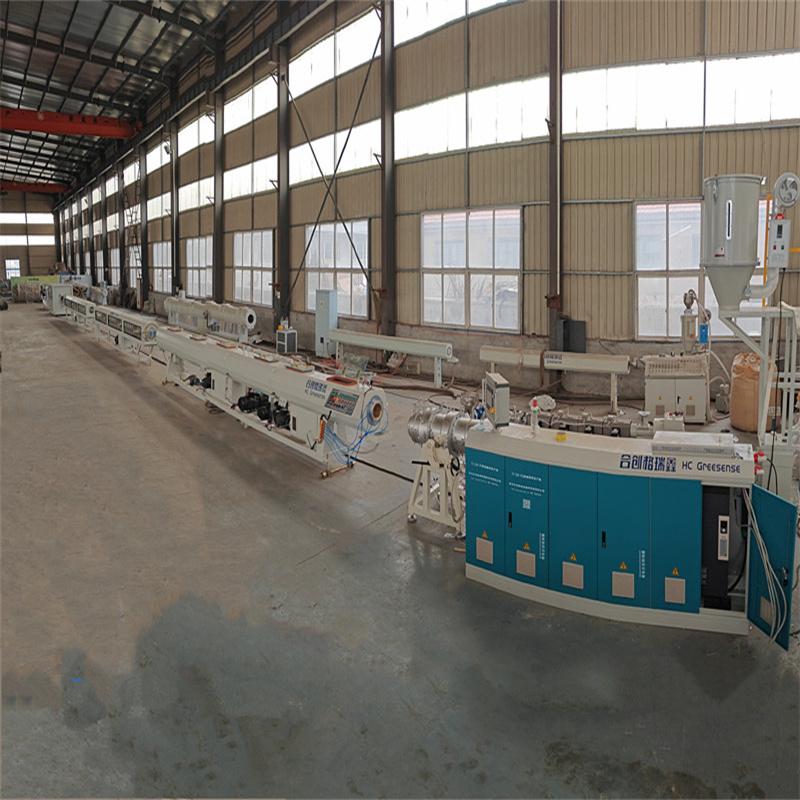

Hdpe Pipe Machine production lines are highly automated, ensuring consistent quality and efficiency. The versatility and durability of HDPE pipes make them a preferred choice for modern infrastructure projects worldwide.

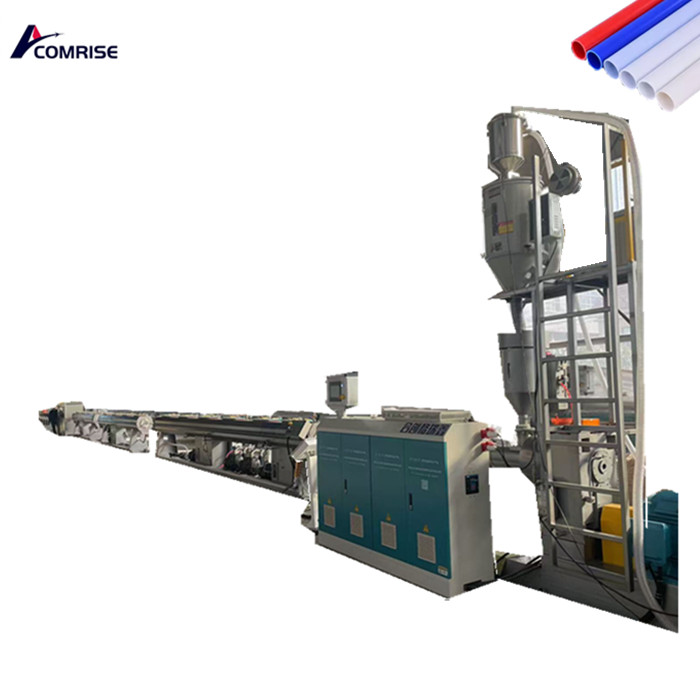

Hdpe Pipe Machine Production Line Composition:

1. Extruder

This is the core component of pipe production. The HDPE raw material is heated and softened, and then extruded through a special opening.

2. Die Head

These softened HDPE will pass through a fixed-shape die and be shaped into a tube of the required thickness.

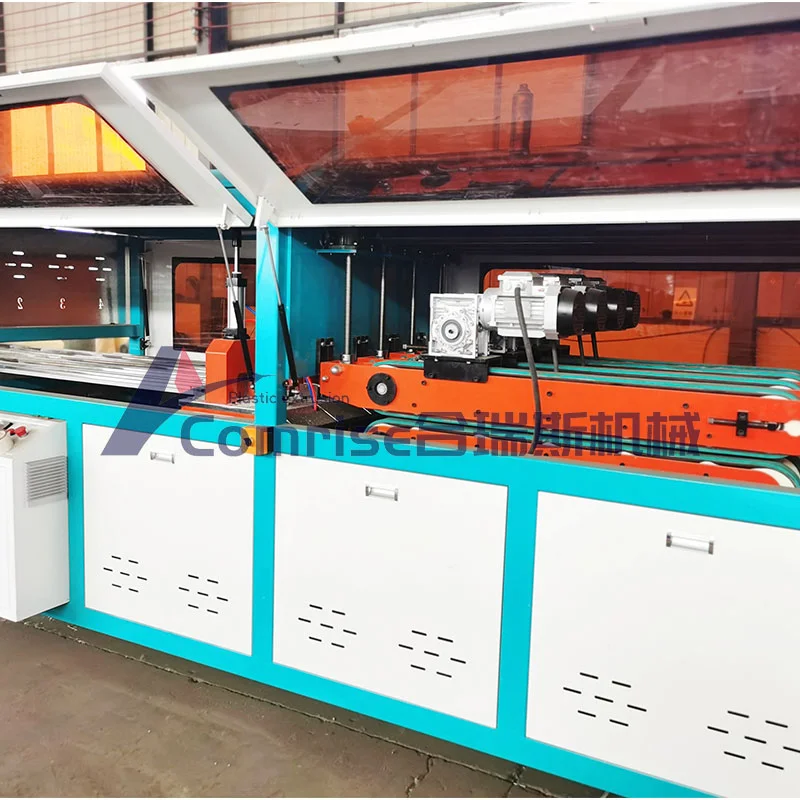

3. Vacuum Calibration Tank

The newly formed pipe enters a special cooling device. In this device, the pipe is quickly cooled and hardened, while ensuring that its shape remains straight and the size meets the requirements.

4. Haul-Off Unit

Pulls the pipe through the production line at a controlled speed.

5. Cooling Tank

Further cools the pipe to ensure it retains its structural integrity.

6. Cutting Device

Cuts the pipe to specified lengths.

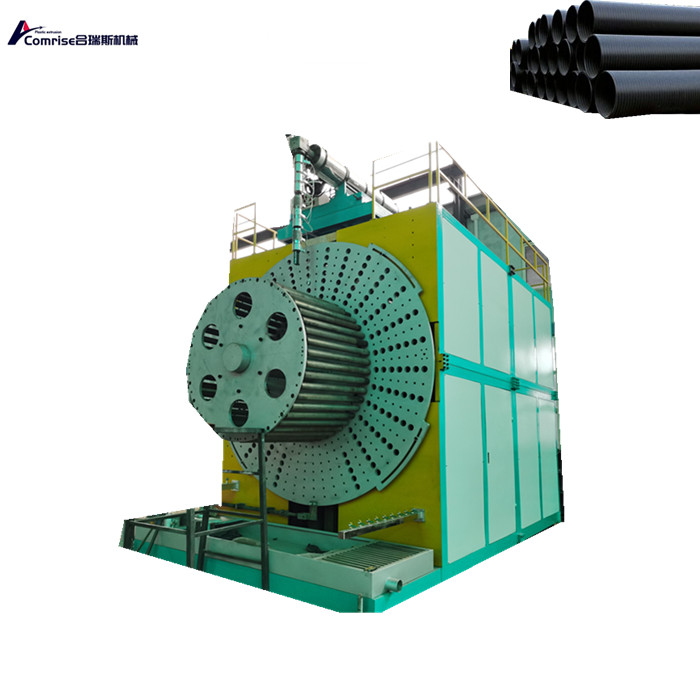

7. Stacker or Coiler

Collects and organizes the finished pipes for storage or transport.

Hdpe Pipe Machine Applications:

HDPE pipes are used in a wide variety of applications. They are used to reliably transport drinking water, thanks to their tight connections and resistance to a wide range of substances.

They are also suitable for transporting natural gas, as they are strong and have the necessary bending properties. In sewage and drainage systems, HDPE pipes cope well with abrasion and corrosion.

In addition, they are a popular choice for safely transporting special liquids and slurries in industrial environments such as the chemical industry and mining.

GET A QUOTATION NOW