断熱パイプマシン

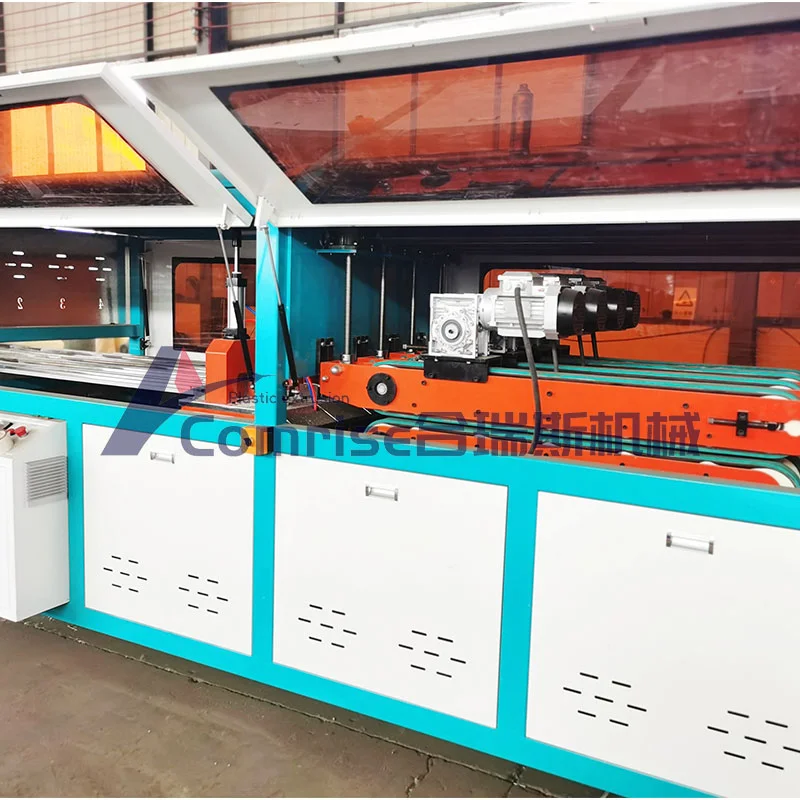

Why choose Comrise PE anti-corrosion insulation pipe machine?

China Top manufacture COMRISE specializing in the manufacturing of PE anti-corrosion insulation pipe machine, single or multi-layers hdpe mpp water pipe machine with high efficient extruder and high output, the extruder use SJ65, SJ75, SJ90 or SJ120 with the newest design and high ratio 38:1, the output two or three times higher than normal design, this why are mostly Chinese and abroad customers now replace their old ones and chase for high output machine. COMRISE are technical company with over 20+ years of experience in the industry, PE anti-corrosion insulation pipe machine has a mature and professional team of engineers and customer service representatives. Comrise are dedicated to providing top-of-the-line products and services, with strict quality control measures.

GET A QUOTATION NOW

PE anti-corrosion insulation pipe machine introduction

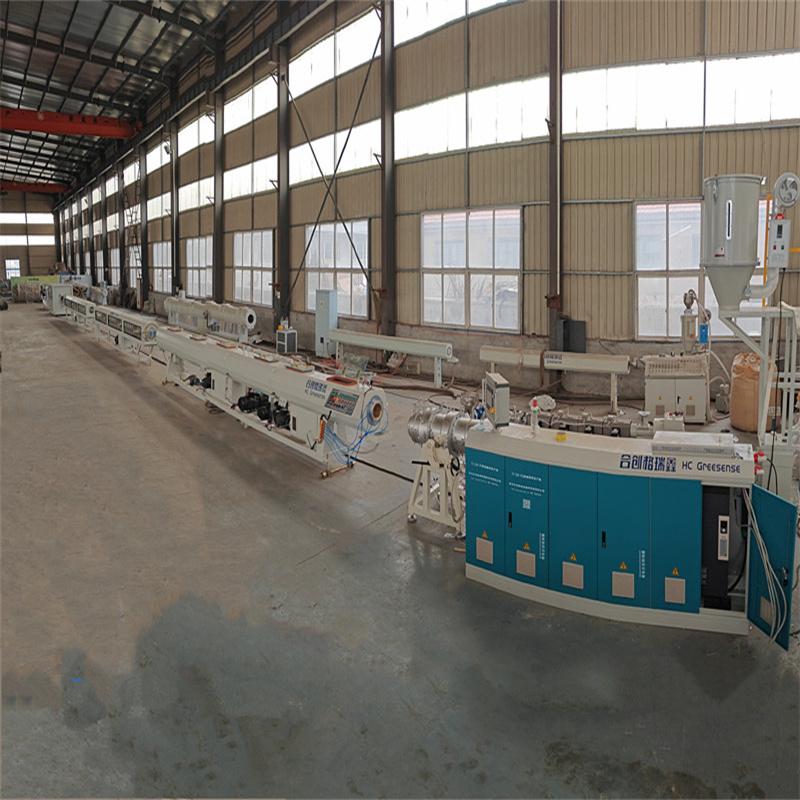

PE anti-corrosion insulation pipe machine production line (φ90-φ2000) is a new pipe production line developed by Comrise company based on foreign pipe extrusion technology and combined comrise years of real production experience. This PE anti-corrosion insulation pipe machine consists of extruder, mould, vacuum sizing box, tractor, cutting machine, unloading rack and dry mixer. PE anti-corrosion insulation pipe machine has the characteristics of high automation, high production, stable performance and long service of life. PE anti-corrosion insulation pipe machine is currently the most advanced and high-quality anti-corrosion and thermal insulation pipe production line in the world.

Comrise PE anti-corrosion insulation pipe machine parameters:

|

Model |

PE-420/960 |

PE-850/1380 |

PE-960/1680 |

|

Extruder model |

SJ-90/33 |

SJ-120/33 |

SJ-150/33 |

|

Pipe specification |

¢420-¢960mm |

¢850-¢1380mm |

¢960-¢1680mm |

|

Production capacity |

550-700Kg/h |

700-900 Kg/h |

800-1200 Kg/h |

|

Installation power |

380KW |

440KW |

580KW |

|

Production line length |

36m |

40m |

48m |

Finished products photos:

Comrise 3PE anti corrosion coating pipe production line introduction:

The full name of 3PE anti corrosion coating pipe production line in Chinese is 3-layer structure polyethylene anti-corrosion steel pipe machine. It is a pipe in which the main steel pipe required by the project has undergone rigorous rust removal treatment, and then the outer wall is coated with 3PE (3-layer structure polyethylene) anti-corrosion medium. . The 3PE anti corrosion coating pipe production line structure is divided into three layers, one is a thermally bonded epoxy powder layer, and the second and third layers are winding layers bonded with adhesive and polyethylene.3PE anti corrosion coating pipe production line base materials include seamless steel pipes, spiral steel pipes and straight seam steel pipes. The three-layer polyethylene (3PE) anti-corrosion coating has been widely used in the oil pipeline industry due to its good corrosion resistance, water vapor permeability resistance and mechanical properties. The 3PE anti corrosion coating pipe production line is crucial to the life of buried pipelines. Some pipelines of the same material will not corrode after being buried underground for decades, while others will leak within a few years. It is because they use different external anti-corrosion layers.

GET A QUOTATION NOW

Comrise 3PE anti corrosion coating pipe production line generally consists of 3 layers of structure:

|

Desc. |

Material |

Thickness |

|

Base layer |

epoxy powder |

(FBE>100um) 60-80 |

|

Middle layer |

adhesive (AD) |

170~250um |

|

Outlayer |

polyethylene (PE) |

1.8~3.7mm |

Comrise 3PE anti corrosion coating pipe production line finished products photos:

GET A QUOTATION NOW

- View as

HDPE断熱パイプ押出機

Comrise 社は、幅広い用途に対応する高品質のプラスチック機械の製造を専門としています。当社は、HDPE水道管機械、HDPE断熱管押出機、PVCパイプ機械、プラスチックシート機械、プラスチックボード機械など、幅広い機械を在庫しています。

配管工、請負業者、製造業者のいずれであっても、Comrise は水輸送と断熱のニーズを満たす完璧なソリューションを提供します。 Comrise hdpe 断熱パイプ押出機は、使いやすく、効率的で信頼性が高いように設計されており、最初から作業を正しく完了するために必要な自信を与えます。では、なぜそれ以下のもので妥協するのでしょうか?パイプ溶接と断熱のあらゆるニーズに対応するコムライズをお選びください。