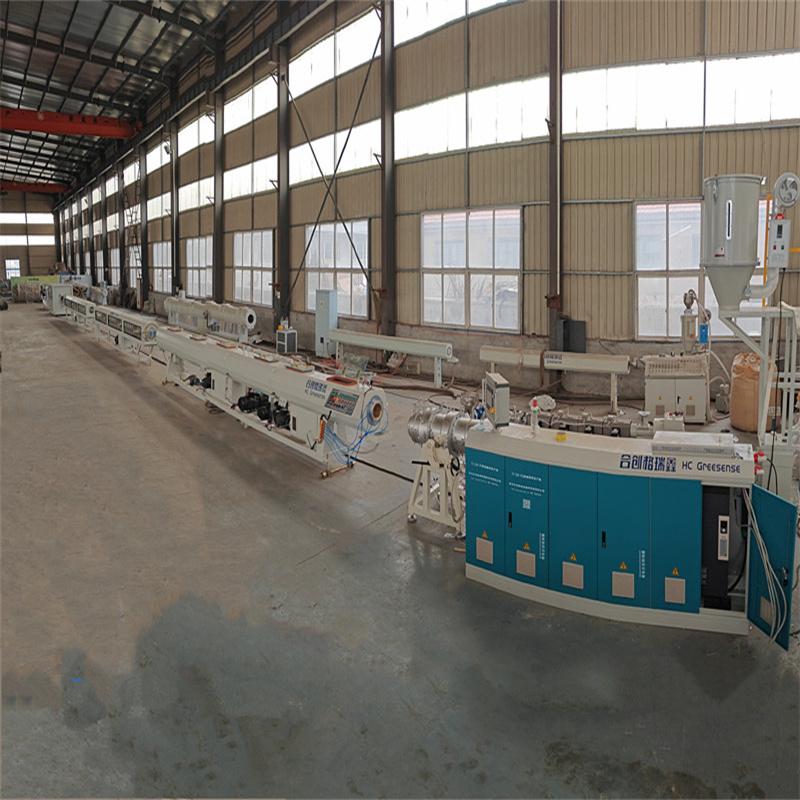

PE PPRパイプ押出生産ライン

お問い合わせを送信

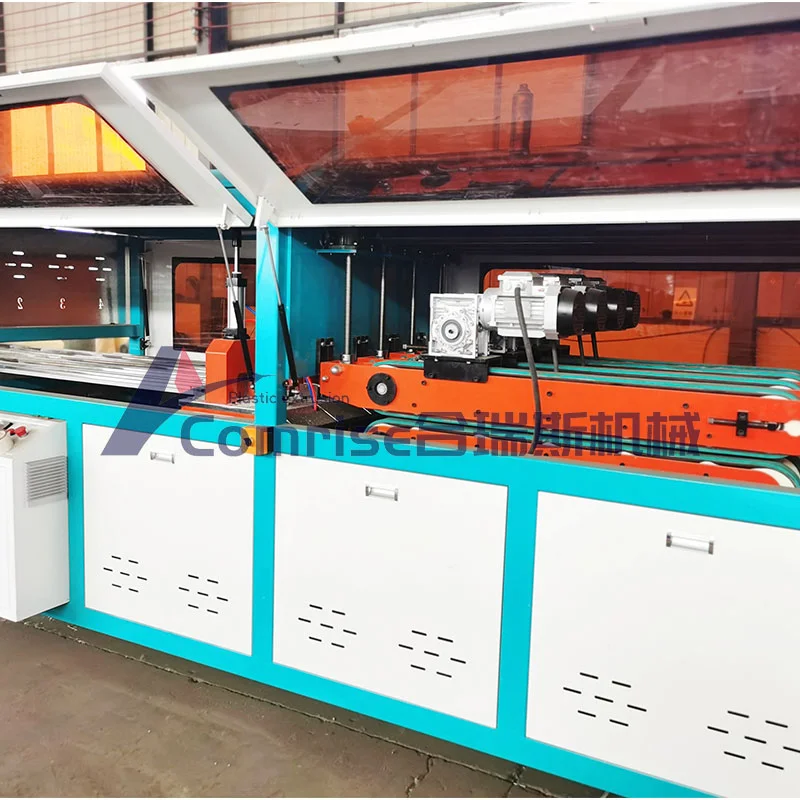

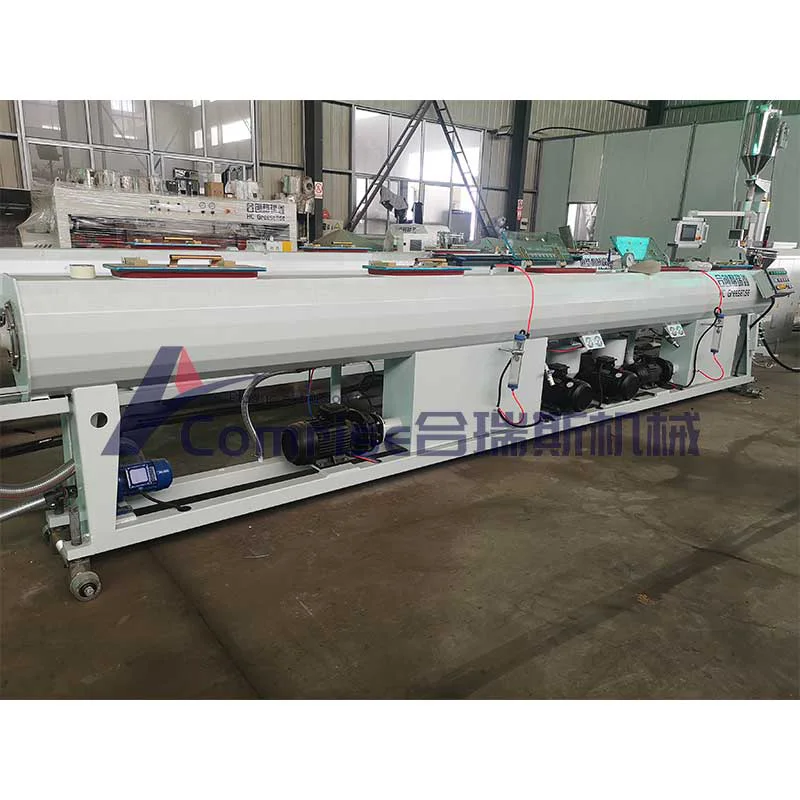

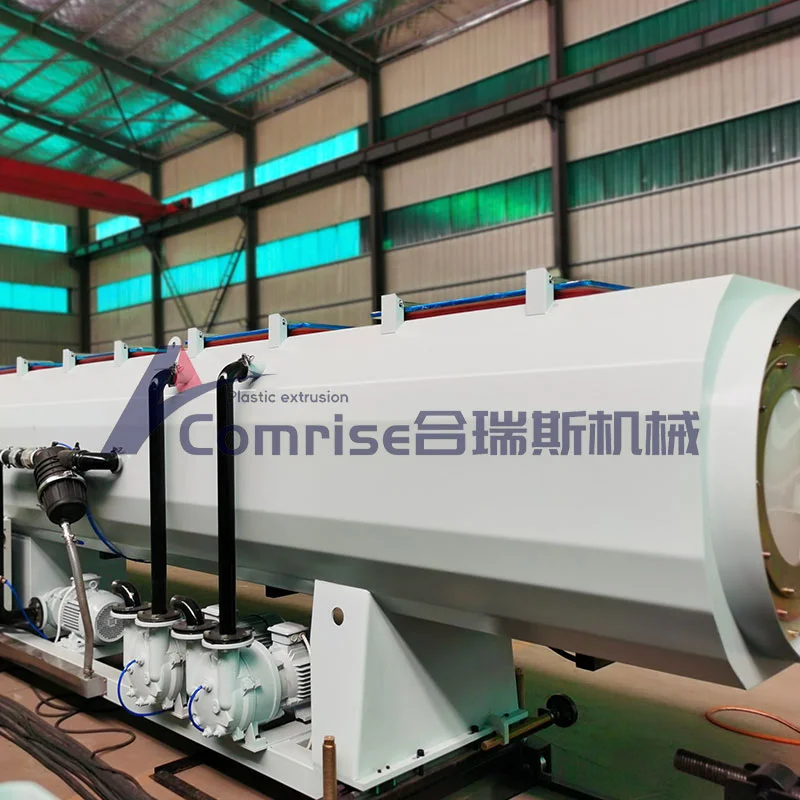

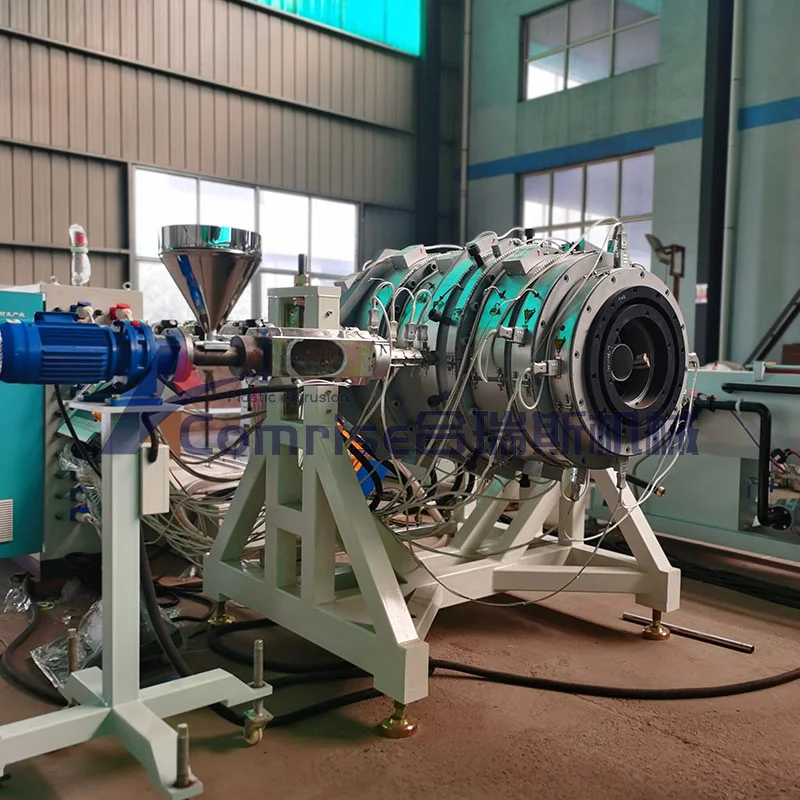

Comrise PE PPRパイプ押出生産ラインは、さまざまなサイズの高出力HDPE PEパイプとチューブを生産するように設計された高度な機器です。 PE PPRパイプ押出生産ラインは、ユーザーフレンドリーであるだけでなく、市場の他の押出機マシンから際立っているいくつかの機能もあります。

アプリケーション:

Comrisepe PPRパイプ押出生産ラインマシンは、さまざまな産業でガス、水、下水などの液体を輸送するために広く使用されています。そのアプリケーションには次のものが含まれます。

1。給水:PEパイプは、軽量、延性、耐食性のために給水システムで使用されます。

2。ガス分布:PE PPRパイプ押出生産ラインを介して生産されるパイプは、漏れがなく、高圧システムに耐えることができるため、ガス配布システムに最適です。

3。下水:PEパイプは、化学攻撃や廃水に抵抗する能力のため、下水システムに最適です。

今すぐ引用してください

PE PPRパイプ押出生産ラインの1メートルあたりの重量

|

HDPE水供給パイプマシンのメートルテーブルあたりの重量 |

||||||||||

|

の |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

|||||

|

|

Pressurempa |

|||||||||

|

|

0.6 |

0.8 |

1.0 |

1.25 |

1.6 |

|||||

|

|

壁の厚さ |

重さ |

壁の厚さ |

重さ |

壁の厚さ |

重さ |

壁の厚さ |

重さ |

壁の厚さ |

重さ |

|

φ20 |

|

|

1.2 |

0.068 |

1.5 |

0.084 |

1.8 |

0.099 |

2.3 |

0.123 |

|

φ25 |

|

|

1.4 |

0.100 |

1.8 |

0.126 |

2.2 |

0.151 |

2.3 |

0.157 |

|

φ32 |

1.2 |

0.111 |

1.5 |

0.138 |

1.9 |

0.172 |

2.4 |

0.214 |

3 |

0.262 |

|

φ40 |

1.4 |

0.163 |

1.9 |

0.218 |

2.3 |

0.262 |

2.9 |

0.324 |

3.7 |

0.405 |

|

φ50 |

1.8 |

0.262 |

2.3 |

0.331 |

2.9 |

0.412 |

3.7 |

0.517 |

4.6 |

0.630 |

|

φ63 |

2.2 |

0.403 |

3.0 |

0.543 |

3.7 |

0.662 |

4.7 |

0.826 |

5.8 |

1.001 |

|

φ75 |

2.6 |

0.558 |

3.5 |

0.755 |

4.5 |

0.957 |

5.6 |

1.172 |

6.8 |

1.299 |

|

φ90 |

3.2 |

0.838 |

4.3 |

1.111 |

5.4 |

1.378 |

6.7 |

1.683 |

8.2 |

2.023 |

|

φ110 |

4.2 |

1.340 |

5.3 |

1.574 |

6.6 |

2.058 |

8.1 |

2.489 |

10.0 |

3.016 |

|

φ125 |

4.8 |

1.740 |

6.0 |

2.153 |

7.4 |

2.625 |

9.2 |

3.213 |

11.4 |

3.906 |

|

φ140 |

5.4 |

2.192 |

6.7 |

2.694 |

8.3 |

3.297 |

10.3 |

4.029 |

12.7 |

4.876 |

|

φ160 |

6.2 |

2.876 |

7.7 |

3.537 |

9.5 |

4.312 |

11.8 |

5.274 |

14.6 |

6.402 |

|

φ180 |

6.9 |

3.602 |

8.6 |

4.446 |

10.7 |

5.453 |

13.3 |

6.687 |

16.4 |

8.098 |

|

φ200 |

7.7 |

4.466 |

9.6 |

5.513 |

11.9 |

6.751 |

14.7 |

8.216 |

18.2 |

9.979 |

|

φ225 |

8.7 |

5.644 |

10.8 |

6.977 |

13.4 |

8.651 |

16.6 |

10.433 |

20.5 |

12.643 |

|

φ250 |

9.6 |

6.960 |

11.9 |

8.545 |

14.8 |

10.498 |

18.4 |

12.852 |

22.7 |

15.561 |

|

φ280 |

10.7 |

8.690 |

13.4 |

10.774 |

16.6 |

13.187 |

20.6 |

16.116 |

25.4 |

19.503 |

|

φ315 |

12.1 |

11.054 |

15.0 |

13.572 |

18.7 |

16.711 |

23.2 |

20.417 |

28.6 |

24.703 |

|

φ355 |

13.6 |

14.003 |

16.9 |

17.233 |

21.1 |

21.248 |

26.1 |

25.889 |

32.2 |

31.348 |

|

φ400 |

15.3 |

17.751 |

19.1 |

21.941 |

23.7 |

26.897 |

29.4 |

32.860 |

36.3 |

39.817 |

|

φ450 |

17.2 |

22.451 |

21.5 |

27.834 |

26.7 |

34.086 |

33.1 |

41.618 |

40.9 |

50.463 |

|

φ500 |

19.1 |

27.702 |

23.9 |

34.317 |

29.7 |

42.126 |

36.8 |

51.408 |

45.4 |

62.245 |

|

φ560 |

21.4 |

34.761 |

26.7 |

42.944 |

33.2 |

52.747 |

41.2 |

64.464 |

50.8 |

78.013 |

|

φ630 |

24.1 |

44.039 |

30.0 |

54.286 |

37.4 |

66.842 |

46.3 |

81.506 |

57.2 |

98.818 |

|

φ710 |

27.2 |

56.012 |

33.9 |

69.124 |

42.1 |

84.803 |

52.2 |

103.557 |

64.5 |

125.741 |

|

φ800 |

30.6 |

71.005 |

38.1 |

87.547 |

47.4 |

107.587 |

58.8 |

121.441 |

72.6 |

159.466 |

PE給水パイプ標準 - (GB/T 13663-2000)

この標準は、製品仕様、技術要件、テスト方法、検査ルール、マーキング、パッケージング、輸送、ストレージを指定します。この標準は、分類システムを含む原材料の基本的なパフォーマンス要件も指定しています。

この標準は、PE63、PE 80、およびPE 100材料で作られた給水パイプに適用されます。パイプの公称圧力は0.32mpa〜1.6mpaで、公称外径は16 mm〜1000 mmです。

この基準で指定されたパイプは、40cを超えない温度での汎用圧力水の伝達と、飲料水の輸送に適しています。

HDPEがHDPE PE PPRパイプに使用されるのはなぜですか?

高密度のポリエチレン(HDPE)パイプは、大量の圧力に耐えることができ、熱可塑性の品質のために錆の影響を受けないことを考えると、液体の大規模な移動に効果的です。従来の金属パイプ継手とは異なり、HDPEパイプは錆びたり、腐食したり、腐ったりしません。

製品アプリケーションシナリオ