プラスチックパイプマシン

Comrise Machineryは、プロの中国のプラスチックですHDPE PP PPR MPPプラスチックパイプマシントップ製造および中国PVCパイプマシンサプライヤー。新世代の父子プラスチック押出機の製造として。父の世代は、これまでさらに30年間プラスチックパイプマシンの押出業界に参入した技術者の最初のグループでした。息子と娘は、大学で機械的なデザインと絵を専攻しました。卒業後、彼らはプラスチックパイプマシンの生産、製造、設計、プラスチックパイプ押出機の開発に従事しています。したがって、品質、技術、革新が同社の利点です。

今すぐ引用してください

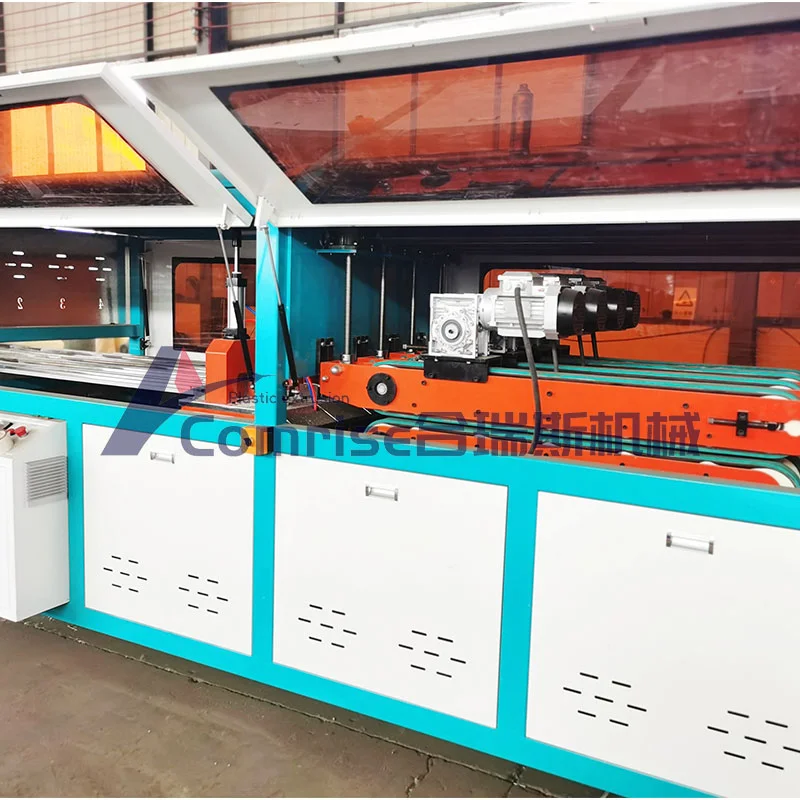

卸売高速プラスチックHDPEパイプマシンの生産ライン

Comriseの主要生産ラインは、高速プラスチックHDPE PP PVC MPPパイプマシン、HDPE腐食および断熱パイプ生産ライン、HDPE大径の中空壁巻きパイプ生産ライン、プラスチック製のシングル/ダブルパイプ生産ラインなどです。

彼らのプラスチックパイプマシンは、高出力、より速いライン速度、安定した高品質で最高の価格で、販売後の時間通りに大きな利点があります。プラスチックパイプマシンは、すべてのコンポーネントがSiemens、Schneider、Smartech、Omronなどの有名なブランドを採用しているためです。 Comriseは、プラスチックマシンの七面鳥のソリューションと世界的な企業へのサービスを供給します。

プラスチックパイプマシンの主な機能は何ですか?

1.高効率のプラスチックPEパイプマシン押出機:強制冷却、逆冷却、逆スパイラル溝の給餌セクション、高速、低ノイズ、硬質ギアボックス、高出力、低い材料融解温度、優れた省エネ効果を備えた

スパイラルフロー分散コンポジットPEパイプダイヘッドカビを備えた2peプラスチックパイプ押出ライン:溶融圧力と流れが変動せずに均一であることを確認します。完成したPEパイプは密度が高く、表面は滑らかで、流れのマークはありません。

3.PE PVCプラスチックパイプ生産ライン真空サイジングと冷却システム:積層サイジングスリーブが採用され、冷却速度と高効率が高く、水タンクはステンレス鋼でできています。

4.プラスチックパイプマシントラクション:2クローまたはマルチクロートラクターマシン、周波数変換速度調整。

5.プラスチックPPVCパイプマシンカッター:大口径と厚壁のパイプを切断できる惑星切断機

6.SJ25またはSJ30マーキングライン押出機:マシンヘッドに沿って、共存マーキングライン

今すぐ引用してください

Comrise高効率HDPEプラスチックパイプマシンの生産ラインパラメーター:

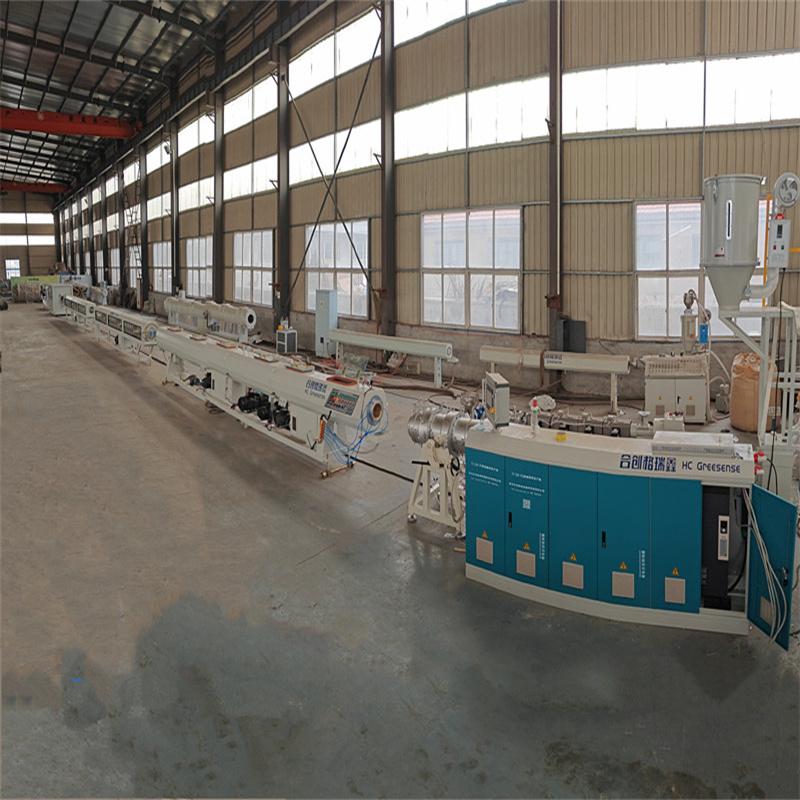

Comrise Plastic HDPE PEガスパイプマシン生産リネコムリーズプラスチックPEおよびPPガス水供給会社が生産するPPガス供給パイプ生産ラインは、主に農業用水と排水、建物の給水と排水、ケーブル敷設などの生産に使用されます。制御デバイス、および真空ポンプとトラクションモーターはすべて高品質の製品で作られています。プラスチックパイプマシントラクションマシンには、2クロー、3クロー、4クロー、6クロー、8クロー、10クロー、12クロー、その他のトラクションモードがあります。プラスチックパイプマシンのチップレスカッティング、ソーブレード切断または惑星の切断を選択できます。プラスチックパイプマシンには、信頼性の高いパフォーマンスと生産効率が高くなっています。ユーザーの要件によれば、同社は特別な機器を装備して、内壁のスパイラルパイプ、内壁中空パイプ、コア層フォームパイプユニットを生産して押し出しを交換できます。 PP、PE、ABS、PPR、PEX、シリコンコアパイプおよびその他の材料を生成できます。パイプ。惑星切断機は、完全に自動的なコンピューター数値制御を採用しています。これは、簡単な動作と信頼性の高いパフォーマンスの利点があります。

HDPE PEガスパイプマシンの仕様とパラメーター:

|

モデル |

PE-75 |

PE-160 |

PE-250 |

PE-400 |

PE-500 |

PE-630 |

PE-800 |

|

メインの押出機 |

SJ-50*33 |

SJ-65*33 |

SJ-65*33 |

SJ-80*33 |

SI-90*33 |

SJ-100*33 |

SJ-120*33 |

|

補助モード |

SJ-30*25 |

SJ-65*33 |

SJ-65*33 |

SJ-65*33 |

SJ-65*33 |

SJ-45*33 |

SJ-45*33 |

|

直径範囲 |

16-75mm |

63-160mm |

90-25mm |

200-400mm |

280-500mm |

350-630mm |

500-800mm |

|

出力 |

150 |

250 |

300 |

500 |

750 |

900 |

1200 |

|

生成速度 |

1-16 |

0.5-12 |

0.2-4 |

0.2-2 |

0.1-1.5 |

0.06-1.5 |

0.05-1 |

|

総設置電源 |

80 |

150 |

200 |

260 |

360 |

430 |

600 |

Comrise HDPE PEガスプラスチックパイプ押出ラインの利点:

1。高効率のプラスチックパイプ押出機機械:強制冷却、逆冷却、逆スパイラル溝の給餌セクション、高速および低ノイズの硬毛の表面還元ボックス、高出力、低い退屈な融解温度、良好なエネルギー節約効果を備えています。

2。プラスチックパイプ製造機械製スパイラルスプリットフローコンポジットダイ:変動、密な製品、滑らかな表面、流れのない均一な溶融圧と流れを確保します。

3.プラスチック押出機の真空サイジングと冷却システム:積極的なサイジングスリーブを採用しています。水タンクはステンレス鋼で作られています。

4。プラスチックパイプ製造機械牽引:可変周波数速度調整を備えた2クローまたはマルチクロートラクションマシンを使用します。

5。切断用のプラスチック押出機:惑星切断、厚い壁のパイプ6を切ることができます6。マーキングライン:マシンヘッドに沿って、共存するマーキングライン

プラスチックパイプマシンアプリケーションフィールドは何ですか?

1。都市水道管ネットワークシステム。

2。都市および農村の飲料水パイプライン。

3。農業灌漑パイプ。

4。マインモルタル輸送パイプライン。

5。郵便および電気配線の保護ケーシングおよび電源線。

6。石油およびガス輸送パイプライン。

7.化学産業、化学繊維、食品、林業、印刷、染色、医薬品、光産業、製紙、冶金、その他の産業における材料および液体輸送パイプライン。

なぜ私たちを選ぶのですか?

- プラスチック機械分野での長年の経験

- 独自のR&Dチームを持っています

- AからZへの完全な解決策

- プロの製造

- 信頼できる保証

- 海外でエージェントを探しています

今すぐ引用してください

- View as

割引価格でHDPEパイプの生産ラインを販売します

清dao Comrise Machineryメイン生産ラインの高効率を含むHDPEパイプ生産ラインを割引価格で、PE大規模中空の中空壁巻きパイプ生産ライン、PPR冷水および温水供給パイプ生産ライン、PPPR冷水および温水供給パイプ生産ライン、内rib巻き下水パイプ生産ライン、内側内rib巻き下水パイプ生産ライン、ダブルプラティックコンポジット巻きパイプ生産ライン、連続した巻きパイプライン、PEラインドパイプライン黒いジャケット断熱パイプの生産ラインとPEシート/ボードの生産ライン、。 HCには20種類以上の新製品があり、ロシア、東南アジア、中東、アフリカなど、世界に広く販売されています。

続きを読むお問い合わせを送信波形パイプ押出ライン

Comrise Corrugated Pipe Extrusion Lineは、排水、下水、電気導管、電気通信に広く使用されている波形のプラスチックパイプを生産するために使用される特殊な製造システムです。波形パイプ押出ラインプロセスには、溶融物質(通常はHDPE、PP、PVC、またはその他のポリマー)を押し出し、強度と柔軟性を高めるために波形構造に形成します。

続きを読むお問い合わせを送信高速1つの壁の波形パイプ生産ライン

当社による高速シングルウォールの波形パイプ生産ラインは、ギア操作モジュールとテンプレートを採用し、製品の循環水冷却と空気冷却を達成し、速い生産速度と均一な波形の均一、一貫した縫い目、および滑らかな内側と外壁を確保します。

続きを読むお問い合わせを送信