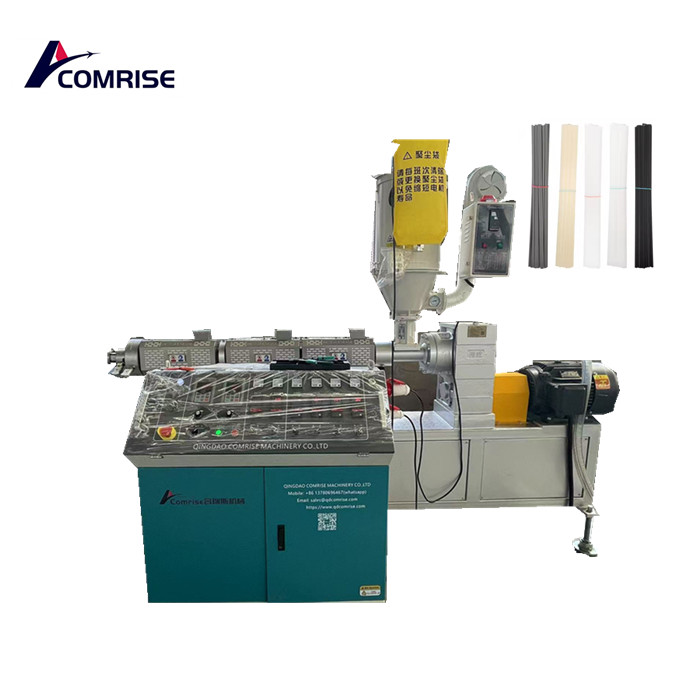

溶接ロッドマシン

お問い合わせを送信

導入:

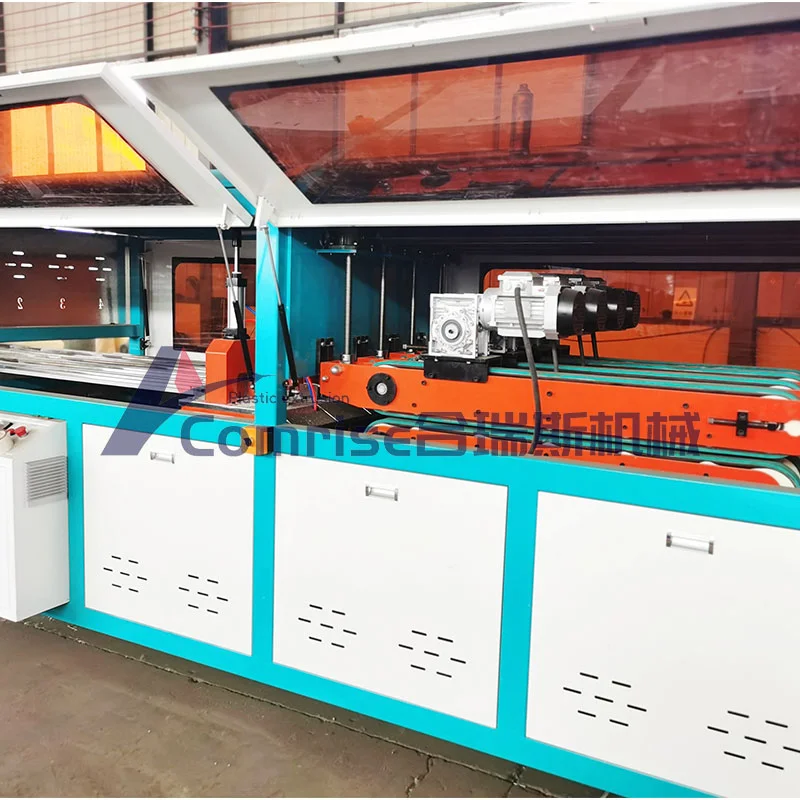

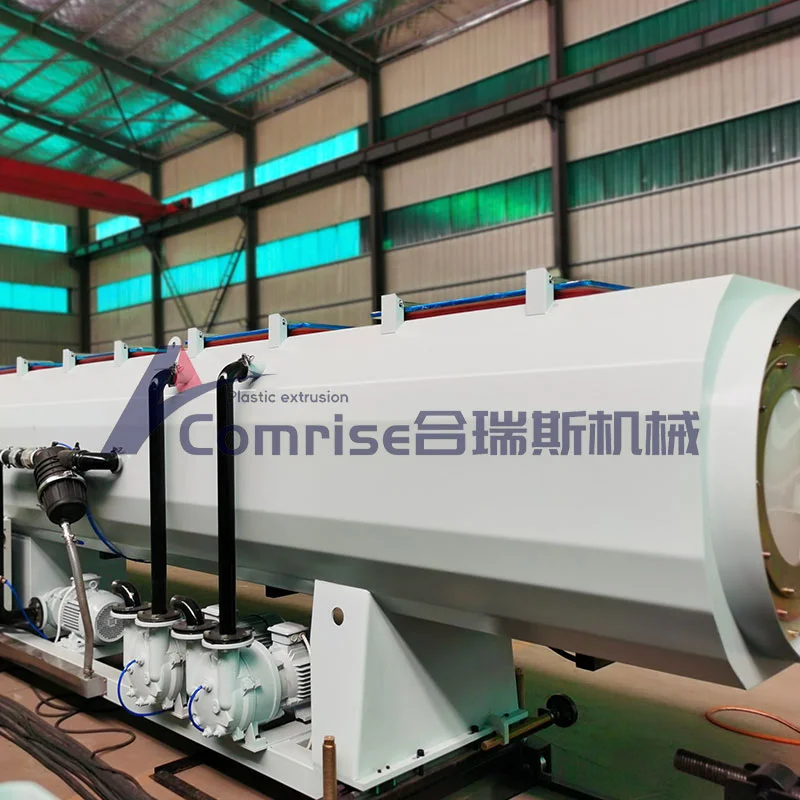

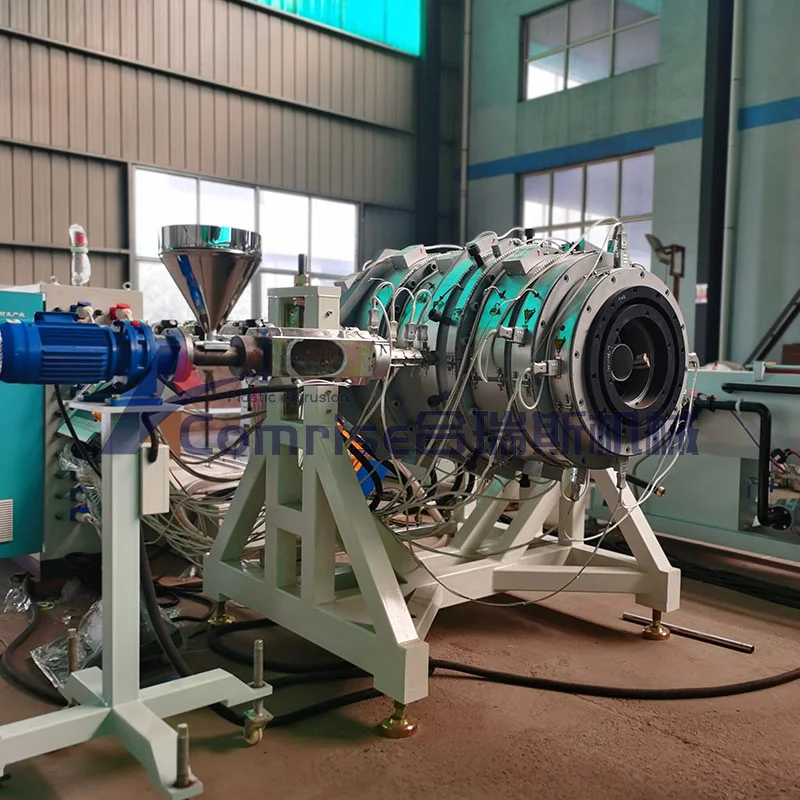

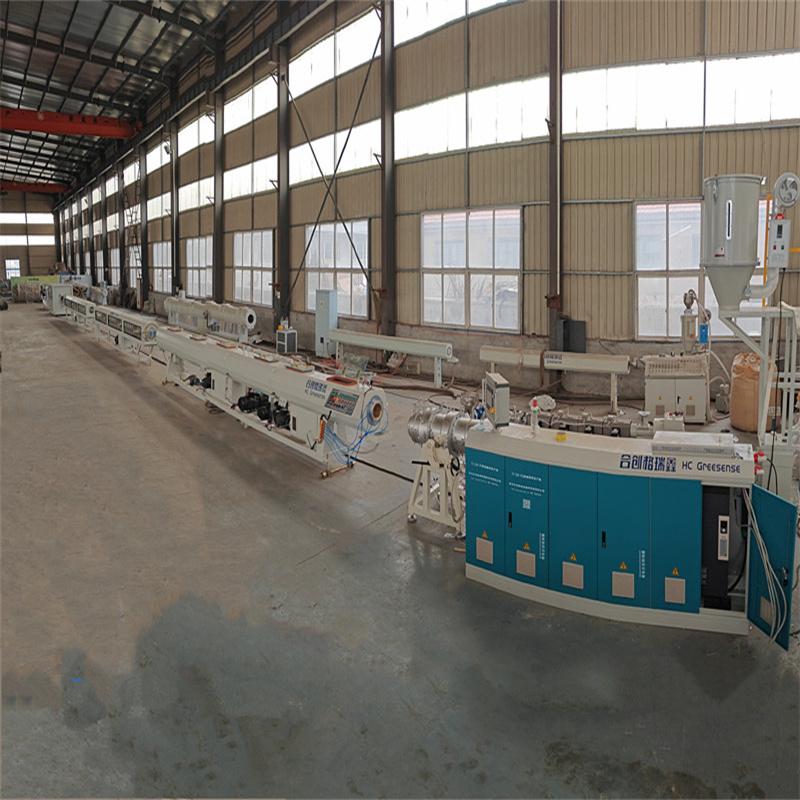

1)The 溶接ロッドマシン 単一のネジ押出機、金型、冷却タンク、トラクションマシン、コイルマシンなどで構成されています。

2) The Welding Rod Machine mold can be circular, double circular/double upright, elliptical, triangular, etc., used for making PP welding rods.

3)溶接ロッド製造機は、PP、PE、PVCなどのプラスチック溶接ロッドを生産するために使用されます。PP溶接ロッドは、プラスチック化学抗腐食、地球膜膜内層、プラスチック容器、パイプ/チューブ、薄い板などの電気めっき装置の溶接に広く使用されています。

4)溶接ロッド製造機は、高出力、低価格、単純な操作、および良好な作業条件を持っています。

応用:

ポリプロピレン(PP)は、溶接が簡単で、多くの異なるプロジェクトで使用できる熱可塑性にもなります。サイズの点で最も安定したポリオレフィンとして、プラスチック溶接ロッドは、パイプラインシステム、ヒュームフード、電気めっき機器の製造に非常に適しています。

材料:PP、PE、LDPE、HDPE、PVCなど

カビの仕様:円形、二重の円/二重の直立、楕円形、三角形など、プラスチック溶接棒の製造に使用される

応用:

半導体機械コンポーネント

航空部品

シーリング要素

ポンプおよびバルブコンポーネント

ベアリングとブッシング(ベアリンググレードピーク)

電気コンポーネント

医療機器部品

食品加工機械コンポーネント

製品機能:

高い機械的強度、剛性、硬さ、丈夫さ、および良好な老化抵抗、

優れた機械的減衰能力、優れたスライドパフォーマンス、優れた耐摩耗性、優れた機械性、

正確で効果的な制御のために、それはクリープなしで良好な寸法の安定性のない良好な耐摩耗性を持っています

応用:

化学機械、腐食防止装置、ギア、およびコンポーネントで広く使用されています。

脆弱な部品、トランスミッション構造コンポーネント、家庭用品部品、自動車製造部品

アンチネジの機械部品、化学機器など。私たちは機械のサプライヤーであり、技術を改善し、製造に努め、長期的なサービスを提供しています

詳細な画像

今すぐ引用してください